אריזות גמישות נמצאות בכל מקום. הן משמשות לציפס, משקאות ורבים אחרים מוצרים. אחת המכונות המרכזיות המשמשות לייצור אריזות אלו היא מכונת הלamination באקסטרוזיה. GSmach הוא יצרן של מכונות אלו. הם עוזרים למפעלים לייצר אריזות עמידות וצבעוניות. היה באמת דרך טובה לשמור על מזון ומשקאות. בעזרת חומרים ומכונות מתאימים, האריזה יכולה להישאר טרייה למשך זמן ממושך יותר. זו דרך חכמה לשמור על הטעם של המזון ולשנות את רמות ההפסד.

ה ר תפקיד מכונות הלamination באקסטרוזיה באריזות גמישות

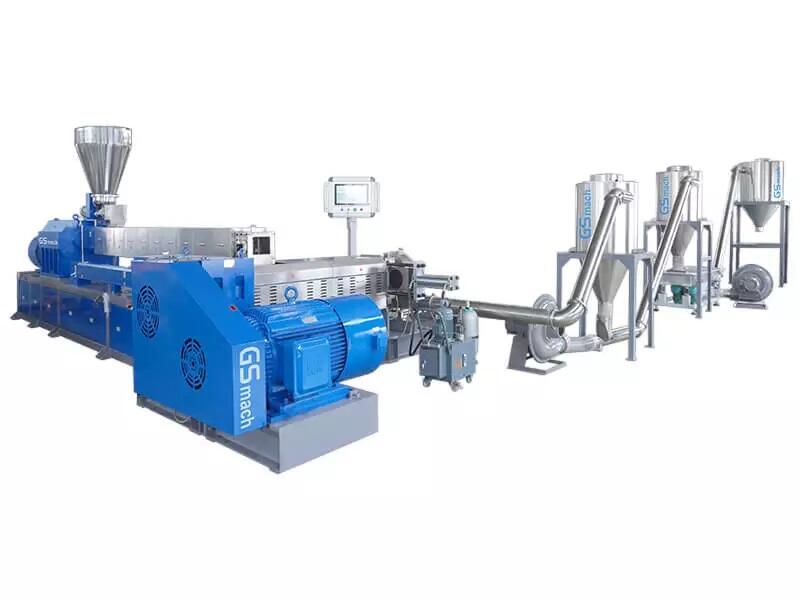

מכונות לamination באקסטרוזיה מהווים חלק גדול בתעשיית אריזות גמישות. מכונות אלו משתמשות בחום כדי לחבר חומרים מסוגים שונים. זה תורם לייצור אריזות חזקות וגמישות שמסוגלות להגן על המוצרים. לדוגמה, בייצור שקית לציפס, השכבה החיצונית עשויה להיות פלסטיק צבעוני. השכבה הפנימית יכולה לעזור לשמור על יובש. כך, הציפס עדיין טעימים וטריים כשפותחים את השקית. הציוד של GSmach מקדם תהליך זה בתנאים כלכליים. הם מחממים את החומרים שלהם עד שמסתכלים חלקית, ואז דוחסים אותם יחד. התהליך גם מונע בזבוז זמן במפעלים. עובדים לא צריכים לעשות כל כך הרבה ידנית, והייצור מהיר יותר. המכונות פועלות גם עם חומרים שונים, ולכן קיימות מגוון אפשרויות אריזה. זה מה שמאפשר לחברות להבדיל בין המוצרים שלהם על המדף. דבר נוסף הוא שהמכונות האלו ידידותיות לסביבה. הן פועלות לצמצום פסולת על ידי יצירת מוצרים עמידים. אריזות עמידות עשויות להפחית נזק ושחיקה, מה שטוב יותר לעסקים וללקוחות.

עורך: איך לamination באקسترוזיה יכול לשפר את איכות האריזה הגמישה

אריזות שמיוצרות ומשופרות באמצעות לamination באקסטרוזיה. אתה שומר על טריות על ידי אריזה טובה של המוצרים. לדוגמה, ניקח בחשבון קופסת ע Juice. ה-juice חייבת להיסגר בצורה הדוקה כדי להישאר תקינה. מכונות של GSmach מבטיחות שהשכבות מחוברות באופן מושלם כדי למנוע חדירת אוויר ו אור. זה חשוב באמת למוצרי חטיפים ולמשקאות. אריזה טובה תוחמת את הטעמים בפנים. היא גם קריטית לבטיחות המזון. אם הבקבוק הוא רך מדי, הוא עלול להתנפץ, מה שעלול לגרום לשפיכות ואיבוד מוצר. והאריזות מדוייקות בצבעים ועיצובים כדי למשוך את תשומת הלב של הלקוחות. הצבעים נשארים בהירים ומושכים הודות ללamination באקסטרוזיה מעולה שמונע את האריזות חזקות כנדרש. כך יהיו יותר אנשים שיתעניינו לקנות את המוצר הזה. לבסוף, צורת האריזה יכולה להשפיע הן על קלות הפתיחה והשימוש. עיצוב אריזה מעולה משפר את החוויה של הלקוח. אז, הודות ללamination באקסטרוזיה, חברות מסוגלות לספק מוצרים איכותיים אלו שגורמים ללקוחות להיות מרוצים. זהו מאפיין מאוד חשוב בתחום האריזות הגמישות.

מהם היתרונות של דחיסה בשכבות בייצור אריזות גמישות?

הדבקת דחיסה היא שלב חשוב בייצור אריזות גמישות, כמו שקיות לקלפים, כיסים לנוזלים וכיסויים למזון. יתרון אחד בהדבקת דחיסה הוא שהיא יוצרת חומר אריזה בעל עמידות ובריאות גבוהות. זה די מרשים, dado שהאריזה צריכה להגן על התוכן שבתוכה מפני גורמים כמו רטיבות, אור ואוויר. כיום, ניתן לאחד שכבות שונות של חומרים באמצעות טכניקת החום של הדבקת דחיסה. כלומר, האריזה הסופית אינה רק חזקה אלא שומרת על המזון טרי לאורך זמן רב יותר. יתרון נוסף הוא התאימות למרבית סוגי החומרים.מותגים יכולים לשלב פלסטיקים, סרטים וחומרים אחרים בדרכים רבות אין ספור כדי ליצור אריזה המתאימה בדיוק לצרכיהם.

יתרה מכך, השימוש בשכבות דחיסה תורם לצמצום הפסולת. שיטות אריזה מסורתיות בדרך כלל מייצרות פסולת שיוצאת לשימוש. אך בשכבות דחיסה, חברות יכולות לנצל כמעט את כל החומר, מה שעושה זאת ידידותי יותר לסביבה. בנוסף, אנשים מעדיפים אריזות בהירות ומושכות. בשיטת שכבות הדחיסה, צבעים ועיצובים יכולים להודפס ישירות על האריזה, כדי להוסיף מראה עינייני. GSmach, כיצרן מכונות שכבות דחיסה, יכול לאפשר לכם לנצל את היתרונות הללו. המכונות שלה מעוצבות כדי לספק שיכבוץ באיכות גבוהה ובמחיר נמוך יותר, כך שחברות יוכלו לייצר בקלות רבה יותר אריזות אופנתיות ורלוונטיות.

איך מכונות שיכבוץ דחיסה מגדילות את יעילות האריזות הגמישות

יעילות היא שם המשחק בייצור, ו מכונה לפלימציה על ידי חימום עוזר לזרום את מהירות ייצור החומרים. האחת היא על ידי האצת התהלים. שיטות קונבנציות ככל הנראה ייקחו זמן רב יותר כדי לשקע את החומרים השונים, בעוד שמכונת לamination בשיטת דחיקה יכולה לבצע את כל אלה בבת אחת. כלומר, יצרנים יוכלו לייצר כמויות גדולות יותר של אריזות בפחות זמן. בנוסף, ציוד זה מעוצב להפעלה קלה, מה שמקצר את זמן האימון הנדרש לمشגיחים חדשים ומצמצם שגיאות ייצור.

GSmach מתמחה בייצור מכונות דחיסה על-ידי דחסית, מדחסים ומכשור לייצור תבניות הזרקה שפשוטים לשימוש על ידי המשתמשים הסופיים. ערך נוסף הוא חיסכון בזמן על ידי מניעת periods של העצרים. מכונות GSmach מעוצבות להיות אמינות, כלומר סבירות נמוכה יותר להתקלקל. אם מכונה מתקלקלת, הייצור מאוחר, וזה עולה כסף וזמן. למכונות של GSmach גם מעצבים תחזוקה נוחה יותר כדי להבטיח פחות עצירות מיותרות לחברות. זה מפחית את הזמן שבו מפסיקים לצורך תיקונים ומשמר את שורות הייצור פעילות. GSmach, לבסוף, גם תורמת לצמצום צריכה של אנרגיה על ידי יצרנים באמצעות יישום טכנולוגיה מתקדמת במכונות שלה. זה אולי קצת משעמם, אני יודע, אבל זה יחסוך לכם כסף בחשבונות האנרגיה ויהיה טוב לסביבה. באותו זמן, אפשר לומר שמכונות הדפסה על-ידי דחיסה ממלאות תפקיד חשוב בהגברת יעילות הייצור ואיכות העבודה של אריזות גמישות.

מתקדי טכנולוגיה של דחית איטום בולטים לייצרנים

עולמ ההארמה הוא מקום שבו רעיונות חדשים תמיד בפיתוח, ולא יוצא ממנו יוצא הדופן טכנולוגית איטום דחית. התפרקות ביולוגית אחד המגמות החמות ביותר כעת הוא התפרקות ביולוגית. אנשים הופכים גם כן יותר מודעים לסביבה ועשויים לחפש אריזות שלא מזיקות לכדור הארץ. חברות, כמו GSmach, פיתוח מכונות לאפשר לייצרנים להריץ חומרים אלו הניתנים לשימור על שורות איטום דחית שלהם. זה אומר שהאריזה יכולה להיות חזקה, מועילה וברת קיימא.

חדשנות נוספת שאני ממש מתרגש לגביה היא מכונות דחפורה מצופות חכמות. זה יכול לכלול דברים כמו חיישים שמניבים את אופן שבו מתקדם תהלית הייצור, אומר הוא. אם יש בעיה או אם החומרים לא מתאימים כראוי, היא יכולה להתריע למשתغل לתקן את זה ברגע זה. פעולה תקנית בזמן אמת מונעת הפסד ותוצרים באיכות נמוכה. הדפסה דיגיטלית עוד נמצאת בשימוש בשילוב עם ציפוי דחפורה. זה אומר שצורות מורכבות וצבעים בוהקים יכולים להודפס ישירות על פני הציפוי. מכונות של GSmach שקדמות את הטרנד החדש, מציעות את האפשרות ליצור אריזות מקוריות בדרך זו, אריזות שמעורות עניין עוזרים למשוך תשומת לב.

לבסוף, אוטומציה היא חלק גדול מהעתיד של הדבקת דחיסה .מערכות אוטומטיות מאפשרות לחברות לייצר אריזות לאורך כל היום עם מעט מאוד מעורבות אנושית. זה לא רק מאיץ את היצוא אלא גם מוביל להפחתת עלויות עבודה. חברות מחשבות קדימה כמו GSmach תמיד מחפשות דרכים לשפר את המכונות שלהן כדי לשרת טוב יותר יצרנים. כל ההתפתחויות הללו בתחום הלימינציה על ידי דחיסה מראות כיצד עולם האריזות הגמישות מתפתח ומשתרע ללא הרף, מה שמספק הזדמנויות רבות הן לחברות והן לצרכנים.