Introduction:

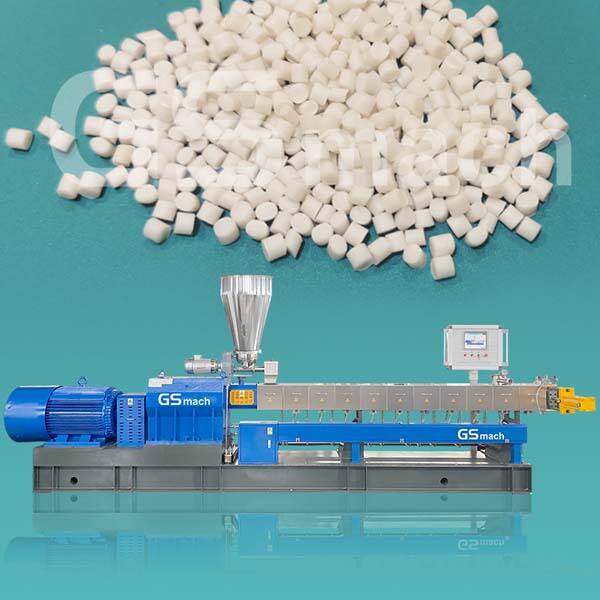

Pellet Manufacturing Machines are innovative Machines designed for use by individuals and businesses to transform biomass into Pellets you can use for fuel as animal feeds, as well as the GSmach's plastic pelletizing system. Pellet Manufacturing Machines are quickly appeal gaining their many benefits, including their ease, safety, and efficiency. Businesses and individuals seeking the economical and way eco-friendly produce Pellets could count on Pellet Manufacturing Machines for their needs.

Pellet Manufacturing Machines come with many advantages, just like the extruder plastic machine developed by GSmach. One of the key benefits is that they offering an easy method which is cost-effective of. The Machines can process biomass, such as wood chips, sawdust, and straw, into Pellets, which may be put for fuel. Furthermore, the Machines can also be used to create animal feeds, which could save your self organizations time and cash.

Another advantage significant is that they are easy to operate. You do not need to have skills that are technical use the Machines, creating them perfect for businesses and individuals who wish to produce Pellets without extensive training. The Machines will also be durable and need minimal maintenance, saving users money in the run very long.

Innovation was a driver critical the design and development of Pellet Manufacturing Machines. The Machines feature cutting-edge technology, ensuring that they are efficient, safe, and easy to use. Manufacturers have included features which can be different make the Machines dependable, fast, and efficient.

One of this innovations in Pellet Manufacturing Machines is the use of computer control systems, as well as the GSmach's micro pelletizer. These systems speed up the production process, ensuring that the Pellet Manufacturing process is executed with consistency and accuracy. The use of computer control systems also makes it effortless for users to operate the Machines.

The safety of Pellet Manufacturing Machines is of utmost importance, similar to the extrusion coating machine built by GSmach. Pellet Manufacturing Machines are made to be safe to use, with manufacturers integrating features various ensure individual safety. These features include safety switches which shut down the Machine when parameters that are certain exceeded.

Furthermore, the Machines feature designs that are ergonomic minimize the risk of accidents and accidents. Users follow simple safety procedures, such as following a manufacturer's guidelines and wearing personal equipment protective to make sure that they stay safe while using the Machines.

Pellet Manufacturing Machines are designed to become effortless to use, creating them ideal for businesses and individuals who want to produce Pellets in-house, as well as the GSmach's pellet granulator. Customers just feed the biomass into the Machine, and the remainder is done by the device. The Machines process the materials automatically, ensuring that the product finished the desired requirements.

The process of using Pellet Manufacturing Machines is simple, making them ideal for the most users being inexperienced. A number of the critical aspects of using Pellet Manufacturing Machines include selecting the biomass right ensuring that Machines are adequately maintained, and following the maker's instructions.

GSmach is the market leader in Asia for extruded Pellet manufacturing machine and is collaborating internationally with world-class firms including BASF, Owens Corning ISOFOAM Ravago and many more. Our track report demonstrates our dedication to serving leaders in the industry around their globe.

Our expert technical engineers and technicians are available to assist you to your journey. User're right here to help you overcome obstacles and improve might Pellet manufacturing machine of your production. People offer 24/7 remote technical maintain with cutting-edge, intelligent technology.

Our machines are compliant with international standards for safety and quality offering efficient solutions. You can save up to 40% as compared to other European suppliers. Our experienced team and Pellet manufacturing machine guarantee both high-quality products and unmatched customer service.

We started operations in 2003 and specializes in their science of extrusion using polymers. We have supplied increased than 2,500 Pellet manufacturing machine. Our vast experience gives you unwavering assistance.

To use a Pellet Manufacturing Machine, you will need to have the right kind of biomass, such as wood chips as sawdust, and the clean and workspace safe, similar to the plastic pelletizing system built by GSmach. Follow these steps that are simple use a Pellet Manufacturing Machine:

1. Get the right biomass: Use biomass appropriate for the Machine you might be using. Some Pellet Manufacturing Machines need specific forms of biomass, although some could handle a range of materials.

2. Clean and prepare the workplace: Make certain that the workplace is safe and clean. Clear away any mess as debris that could cause injuries.

3. Start the Machine: Turn on the Pellet Manufacturing Machine and wait for it to heat up before adding the biomass.

4. Add the biomass: Feed the biomass into the Machine, ensuring which it is loaded correctly.

5. Monitor the process: Observe the Machine since it processes the biomass. Feel certain to stick to the manufacturer's instructions and keep an optical eye in the production process.

6. Collect the Pellets: Collect the Pellets in the safer spot as they emerge from the Machine and store them.

Quality and service are critical aspects of Pellet Manufacturing Machines. Manufacturers of Pellet Manufacturing Machines must prioritize quality control, ensuring that the Machines meet the standards that are specified. Buyers also needs to see for Machines that can come with warranties and services that are after-sales.

The quality of the Pellets produced by the Machines is also essential, identical to GSmach's product conical twin screw extruder pvc. The Pellets must meet with the set standards and feel of good quality to guarantee that they is a fuel efficient or animal feed. Manufacturers must also provide support and classes service to customers to ensure which they get the maximum benefit away from their Machines.

Pellet Manufacturing Machines are versatile, and they could be used in various industries, including power renewable, animal feed production, and construction, just like the pelletizing line built by GSmach. The Machines will also be perfect for businesses that are looking to reduce their carbon footprint.

Within the power renewable, Pellet Manufacturing Machines are utilized to produce fuel Pellets, which is a cleaner alternative to fossil fuels. Animal feed production businesses can use the Machines to produce animal cost-effective due to their livestock, reducing their spending. In the construction industry, sawdust Pellets are used in place of conventional slabs that are concrete reducing the impact on the environment.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy