GSmach is a packaging machine company. They are also known for one of their significant machines, the extrusion laminating machine. This machine makes special packaging materials that preserve food and other products by keeping it fresh for a very lo...

VIEW MORE

Laminating is a nifty way of creating paperboard and cards products which are both stronger and sexier. At GSmach, we design high speed laminations machines for precisely this purpose. The quality of paperboard is improved in various ways by hig...

VIEW MORE

PVC compounding machines in the cable wire worlds of manufacturing It's no secret. These machines combine various materials to make a special kind of plastics known as PVC. If you are interested in purchasing a PVC compounding machine then there...

VIEW MORE

The quality and performance of polymers can be substantially enhanced by using twin screw extrusion technology. As the two screws rotate, they thoroughly blend together all of the material. IntroductionBlending polymers is one of the commonly us...

VIEW MORE

GSMach manufactures machines to package items like food, drinks and other goods. One of the key machines we have is extrusion laminating machine. This unit allows to coat films and foil for packaging. With this machine, businesses can produce flexibl...

VIEW MORE

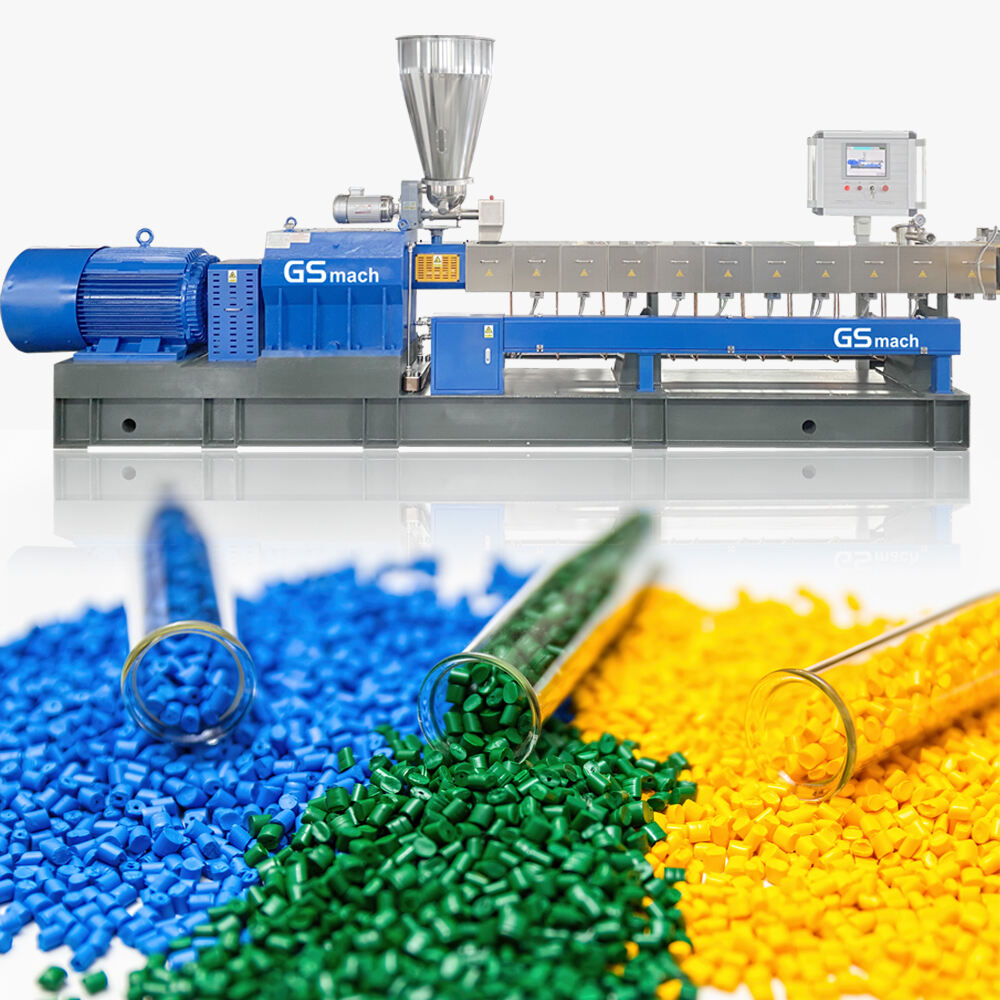

GSmach is a manufacturer of machinery used to produce plastics. Another one of our key pieces of equipment is known as the twin screw extrusion line. This machine is special in that it produces PVC, a kind of plastic, and plastic masterbatch. PVC is ...

VIEW MORE

Today, machines do a lot of the work in factories to make products. One significant machine is the PVC compound. These machines blend a variety of materials to make a special category of plastic known as PVC, or polyvinyl chloride. PVC has plenty of ...

VIEW MORE

A laminator, on the other hand, is a machine designed to laminate paper, giving it strength and longevity. When companies need to prepare labels to affix to products, they can commonly be found in these machines. How to Select the Right Laminati...

VIEW MORE

Sophisticated extrusion laminating machines are key in the production of multilayer films. These extrusion laminate machines laminate various layers of materiaL into a single strong film. They are used in numerous industries, including food pack...

VIEW MORE

PVC compounding machine is a piece of equipment which is utilized in various industries to mix and blend the materials properly. These machines produce various PVC products that we can find in our daily life such as pipes cables and floorings. Busine...

VIEW MORE

Twin screw extrusion lines are key machines for production. They help to mix and shape materials, such as plastic and food. There are a lot of factors that can influence how well these machines work. By knowing that you can help companies (for instan...

VIEW MORE

Lamination machines are an essential tool in the packing world. THEY CAN STRENGTHEN PAPER They can also make paper strong and glossy, something that saves paper from at least some damage. This is fantastic for the environment! And by working with the...

VIEW MORECopyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy