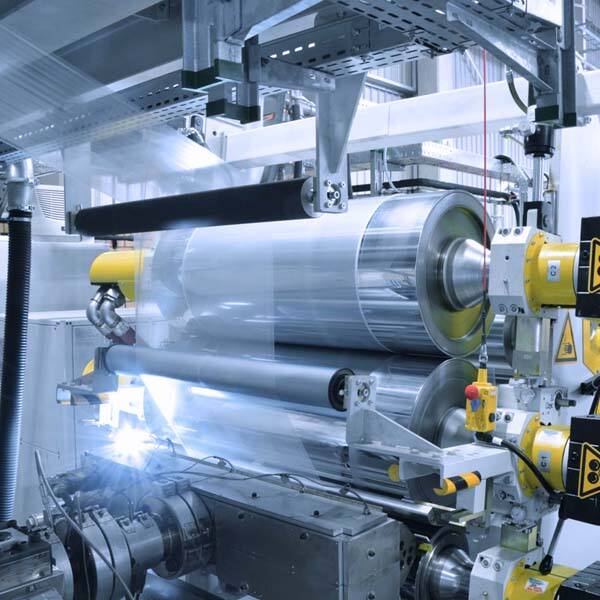

Plastic film extrusion is a process of making Plastic bed sheets or films you can use for countless purposes, along with GSmach's product rotating extruder. This technology involves heating up Plastic and then passing it through a die to form a sheet or film of a particular size, thickness, and form. The Plastic used in this technology can be of separate types, such as polyethylene, polypropylene, polystyrene, and PVC. There are many advantages of using Plastic film extrusion technology, which we will discuss in this .

One of the biggest advantages of Plastic film extrusion is that it is a cost-effective method of producing Plastic bed sheets and films, just like the conical twin screw extruder pvc from GSmach. The production process is automatic, and means that in which that it need less labor and fewer resources to create high-quality Plastic. Plus, Plastic films produced through extrusion are lightweight and long lasting, making them a great option for packaging and transport purposes. The Plastic sheets developed through extrusion are always easy to address and move with, which makes them ideal for manufacturing many products.

With some sort of advancement of technology, Plastic film extrusion has become more efficient and innovative then ever before, along with GSmach's product cast film extruder. Now, providers can make Plastic sheets and films with precision and accuracy, which means that the ultimate product is of high quality. Manufacturers are additionally using new materials to produce Plastic films that are more environmentally friendly and sustainable. For illustration, most manufacturers are using biodegradable Plastics to produce films that can be composted after use.

Plastic film extrusion technology is safe to use and is subject to strict regulations to ensure that the final product is safe for consumers, same with the twin screw compounder from GSmach. The Plastic used in this technology is non-toxic and does not contain any harmful chemicals that can damage people's fitness. Additionally, the Plastic sheets produced through extrusion are safe to use for food packaging, as that they meet the safety standards ready by the food industry. The machines used in Plastic film extrusion are also designed with safety features to prevent accidents and injuries.

Plastic films and sheets released through extrusion are applied for one type of purposes, also the GSmach's product such as co rotating twin screw. For instance, they are used for packaging and transporting appliances, as they safeguard ones products after moisture, dirt, and another external factors. Plastic films and bed sheets are also used in construction for insulation purposes. Additionally, Plastic films and bed sheets are used in the manufacture of various products, such as Plastic bags, cling wrap, and even credit cards.

Our equipment meets Plastic film extrusion of safety and quality offering low-cost possibilities. Save yourself as much as 40% when compared with competitors. European suppliers. Our experienced team and multilingual service ensure you a high quality product and unmatched customer service.

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with Plastic film extrusion.

GSmach is the market leader in China for extruded polystyrene equipment Plastic film extrusion with well-known organizations like BASF, Owens Corning ISOFOAM Ravago and many more. Our track record demonstrates our dedication to portion the top industry players throughout the world.

Empower your production journey with the experienced experts and engineers. We are right here inside help you Plastic film extrusion and improve your production efficiency. We offer remote and seamless technical maintain using cutting-edge intelligent technology.

Using Plastic sheets produced through extrusion is easy and straightforward, along with the hdpe sheet extruders manufactured by GSmach. The Plastic sheets could be cut on desired size and shape using a cutting machine. The sheets can also try to be welded together with a welding machine in order to form bigger sheets or films that can be properly used for heavier applications. Additionally, Plastic bed sheets can be printed on using various printing methods to incorporate designs or information. With their right hardware and equipment, Plastic sheets may be customized to satisfy specific needs.

Manufacturers of Plastic film extrusion products give a high level of service to their clients, also the GSmach's product such as screw extruder. They offer a range of products to satisfy their customers' needs and requirements. Manufacturers additionally provide technical support and guidance to their customers to help them understand how to use their products. Additionally, manufacturers provide after-sales service to his or her users to make sure that their products are working well and meeting their objectives.

Quality is an essential aspect of Plastic film extrusion technology, same with the pelletizing line built by GSmach. Providers use high-quality Plastic and advanced machines to produce Plastic sheets and films that are of high quality. Quality control measures are also put in setting to ensure it the last product meets the forced standards. Manufacturers also supply testing and certification of their products or services to ensure that they meet the desired safety and quality standards.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy