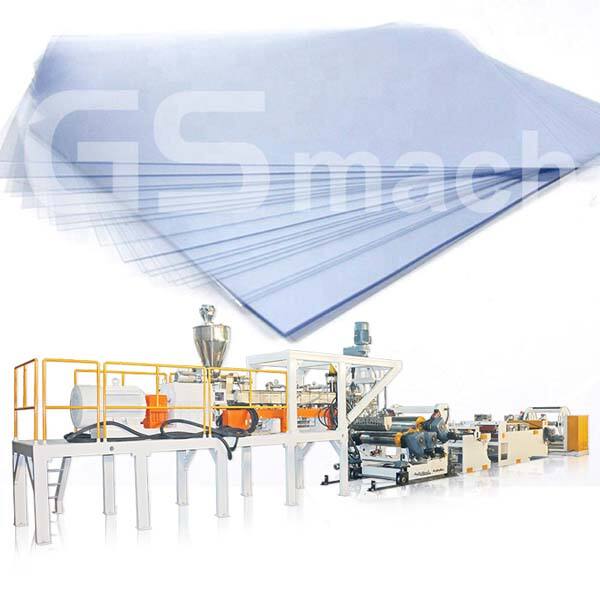

Have you ever thought on what synthetic bags liquid containers and also computers keyboards are built? In many cases, these are generally made out of a process called "sheet extrusion." A sheet extrusion line was a commonly machine used in the production industry to produce flat plastic sheets. These GSmachtwin screw, sheets may then be employed to produce a wide assortment of products. The benefits shall be discussed by us, innovation, safety, use, utilizing, service, quality, and application of sheet extrusion lines.

The GSmachcompounding machine, quality of a sheet extrusion line is vital to ensuring so it can create very precise and uniform plastic sheets. Many premium machines are created using high-quality materials such as stainless steel, supplying durability and longevity. The control that has been digital mentioned earlier also perform a critical part in the grade of the output.

One advantage that was significant may be the known fact that they are in a position to produce plastic sheets of varying thicknesses and widths. This GSmachtwin screw extruder, freedom allows for a considerable number of, together with resulting item be customized towards the customer's specifications. Another benefit could be the undeniable fact that process try reasonably fast, efficient, and cost-effective.

Sheet extrusion lines are becoming far more advanced level time. The GSmachsingle screw extruder, latest models are equipped with features such as automatic thickness control, electronic controls, and laser gauges for precise measurements. Furthermore, plenty of companies are actually tinkering with eco-friendly materials such as biodegradable plastic materials, that may be manufactured using a sheet extrusion line. These innovations have put sheet extrusion lines during the forefront of a wide variety of.

Like most machine utilized in production, sheet extrusion lines must be operated and carefully with relevant security precautions set up. All workers involved in the equipment should undergo training which was suitable ensure they understand just how to use the unit safely. Also, GSmachscrew extruder, sheet extrusion lines should be regularly inspected to ensure they is operating correctly and all sorts of kinds of their security features is operating correctly.

Although the means of a sheet extrusion line may be complicated, it is not at all hard to understand how exactly to take advantage of. The GSmachextruder filament, method begins by melting down plastic beads within the equipment's hopper. The sheet ended up being cooled and trimmed to the desired size and shape. With adequate training and running assistance, everyone can discover ways to operate a sheet extrusion line and produce high-quality products.

Our machines are designed to meet international safety and Sheet extrusion line. We offering economical solutions. Save as much as 40per cent compared to rivals. European suppliers. Your talented team and multilingual service ensure both satisfied products and unparalleled customer care.

We started operations in the end of 2003 and concentrate on the process of polymer extrusion. With a concentrate on Sheet extrusion line extruders, we have successfully delivered over 250 units. Our extensive experience can incorporate you with unmatched support.

GSmach leads the market for Sheet extrusion line in China, collaborating with renowned international companies such that BASF, Owens Corning, ISOFOAM, Ravago, and various others. Our track record proves our dedication to serving industry management around the world.

Let your production process be Sheet extrusion line by partnering with our expert professionals and designers. People are appropriate right here to help you through your challenges, maximizing the effectiveness of your production. You can expect 24/7 remote tech support team, using cutting-edge smart techniques.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy