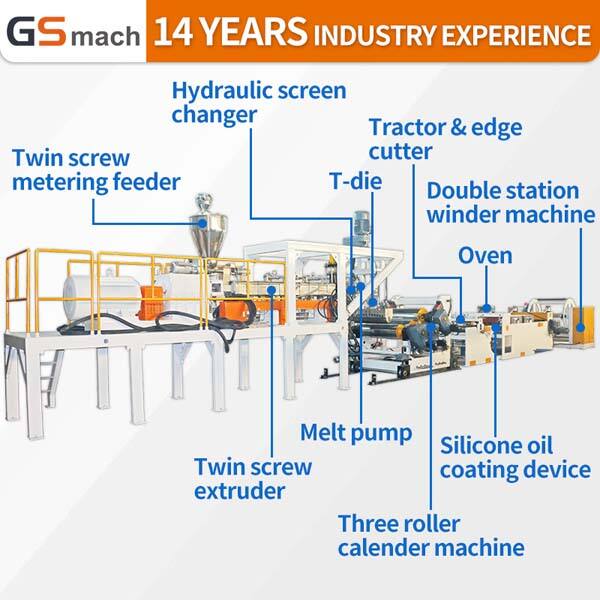

Sheet extrusion machines are unique machines that produce plastic sheets for the various products we use on a daily basis. These machines melt plastic pellets and form them into flat sheets of various sizes and thicknesses. Once the plastic is melted, it’s extruded through a die, which is like a mold that forms the sheet in its final shape

GSmach sheet extrusion is used in many places to produce objects, such as food packaging, signs and even toys. The sheets of plastic that these machines produce can be formed of a variety of types of plastic depending on how stiff or durable the end product needs to be.

It has many great explanations why you would need a sheet extrusion machine to create plastic. One big reason is that these machines can produce a lot of plastic sheets really fast. That’s important to companies that need to produce lots of products quickly. Another advantage is that GSmach extrusion lamination machine produce plastic sheets of consistent quality, which is a contributing factor in ensuring that the end products are of good standard.

When selecting a sheet extrusion machine, you need to consider the type of plastic you will be using, the size and thickness of sheets you require and how much you are willing to spend. You’d also want to look into the reputation of the company that produced the machine and how much of a commitment they have to their customers. GSmach pvc sheet extrusion machine is widely used in lots of industries.

How To Maintain Your Sheet Extrusion Machine In Order To Keep It Running Warn Properly

You will need to establish a regular schedule to maintain the sheet extrusion machine. That’s why good maintenance includes cleaning the machine often, inspecting it for signs of broken parts and making repairs when it is necessary. You also need to be mindful of only using the correct kind plastic pellets, as the wrong type can damage the machine and mean it does not last as long. Get your GSmach sheet extruder machine today!

The new sheet extrusion machines you are getting should be efficient and easy to use, even easy to operate and fast. New models frequently feature special abilities that enable them to produce more products over the course of their life while also producing less waste. Some of its features are auto temp control, touch screen and safety features. Have your GSmach pp sheet extrusion machine now

Our company is established at the end of 2003 and focus regarding science of Sheet extrusion machine using polymers. We concentrate concerning twin-screw extruders, we have successfully delivered over two hundred units. Be confident in our years of experience and unfailing maintain for your extrusion needs.

Empower your production journey with the experienced experts and engineers. We are right here inside help you Sheet extrusion machine and improve your production efficiency. We offer remote and seamless technical maintain using cutting-edge intelligent technology.

GSmach is the market leader in Asia for extruded Sheet extrusion machine and is collaborating internationally with world-class firms including BASF, Owens Corning ISOFOAM Ravago and many more. Our track report demonstrates our dedication to serving leaders in the industry around their globe.

Our machines are compliant with international standards for safety and quality offering Sheet extrusion machine. You can save up to 40% as compared to other European suppliers. Our experienced team and multilingual service guarantee both high-quality products and unmatched client service.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy