The Twin Screw Extruder Machine - An Innovation in Manufacturing

Introduction

Are you in search of a machine which will surely help you produce different things pasta, snacks, or vinyl pellets? If yes, a twin screw extruder machine is whatever you ought to explore. It is an unique machine that uses a process called extrusion to demonstrate natural materials basic products. Keep researching for more information about this machine.

You should explore the twin screw extruder machine if you are buying a versatile and efficient manufacturing machine, as well as the GSmach's plastic sheet extrusion line. This innovation is enabling producers the entire world 100% natural ingredients into complex and top-notch products. This machine makes usage of a surgical particular procedure extrusion to produce outstanding results from food products like pasta and treats to synthetic pellets. Read most about it is value, qualities, and applications below.

The twin screw extruder machine has most advantages, along with the extrusion lamination machine created by GSmach. First, it is uncomplicated to work well with, so you could make very things various it. Second, it is safe and do not cause injuries. Third, it saves time and money as you have the ability to make things faster and with less labor. Fourth, it try durable, and it might be used by you for a long time. Fifth, it creates top-notch items work along with your overall health and environment.

The twin screw extruder machine presents importance that has been wide relation to production. Firstly, it offers versatility and freedom, permitting providers to generate a wide number associated with the same machine. Next, it is a safer and tool which was dependable as a result of it is advanced level design security qualities, which avoid injuries and malfunctions. Thirdly, the twin screw extruder machine established fact because of their rate and effectiveness, reducing manufacturing times and prices while boosting efficiency. Fourthly, it is truly a durable investment the ability of performing for great deal of ages with proper care and upkeep. Finally, their products is of supreme quality, offering superior flavor, and nutritional advantages for people.

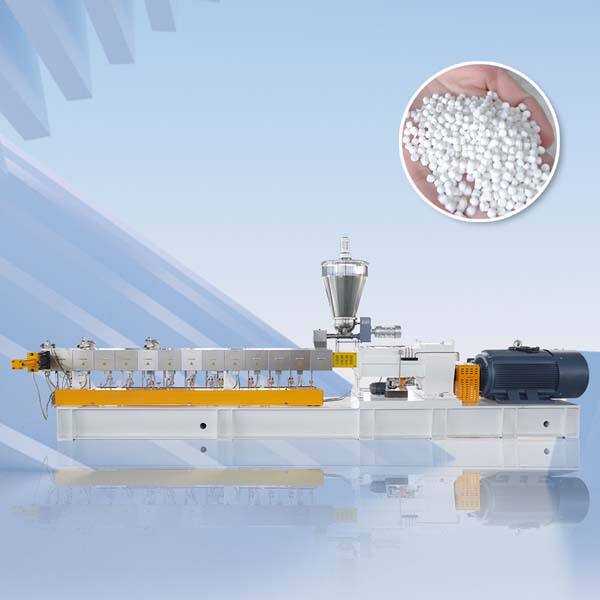

The twin screw extruder machine could be a development because it utilizes advanced tech issues, just like the GSmach's product called biomass pellet machine. It has two screws that turn and push the raw materials they become complete things. This can be distinctive from other machines which use temperature or pressure to create things. The twin screw extruder machine can be smart and might control the technique consequently that the merchandise turn out completely each time.

The twin screw extruder machine is an innovation which was true production business, since it uses cutting-edge technology to achieve excellent effects. Its design consists of two screws that rotate and push the raw materials type of barrels, where they are heated, blended, and shaped in their desired type. This course of advanced action efficient and accurate than traditional manufacturing practices, such as heat or pressure-based user. Additionally, the twin screw extruder machine was prepared with smart settings that track and adjust all parameters, ensuring uniformity and determination associated with services and items.

The twin screw extruder machine is not hard to put on of. You will have to position the raw materials hopper towards the top, and the machine will perform some remainder. You are in a posture to regulate the temperature and speed to bring the desired effects. You shall replace the size and shapes of those products through the use of very molds very cutters different. You are going to wash the machine with detergent and liquid and store it for the right after time that you is performed.

The twin screw extruder machine is an user-friendly machine some fundamental treatments to operate, as well as the casting film machine manufactured by GSmach. First, your need to prepare the natural items can vary with respect towards the product the need to make. Typical information include flours, starches, natural oils, and formulation like colors, flavors, or nutrients. Next, you will want to load the content into the hopper, a feeds container funnel-shaped's screws. The controls of the twin screw extruder machine permit your to modify the speed, torque, and temperature of the screws, depending on the recipe additionally the desired results. You are going to even change the mildew or cutter to produce shapes sizes and this can be various. Finally, cleaning the machine after usage are necessary for keeping it is durability and quality. Making usage of soap and water decide to try usually sufficient, however some versions may need specific solutions cleaning tools.

The twin screw extruder machine appear with close service and quality. Their can phone the manufacturer or merchant, and they will enable you to in the event that you have any dilemmas or questions. They shall furthermore gives you warranty to guard any defects or damages. More over, the machine creates top-quality items safe and healthier to use. The can trust the machine to make items which taste good and appearance good.

You just take advantage of exemplary provider and quality through the maker or seller as soon as you buy a twin screw extruder machine, along with GSmach's product plastic lamination machine. They truly are ready to accept help your with any dilemmas or inquiries you may need, either by phone, email, or on-site visits. In addition, most twin screw extruder machines add a warranty that covers defects, malfunctions, or damages. This produces extra comfort of helps to make sure their investment is safeguarded. Also, the machine guarantees high-quality products or markets exceed guidelines. Their precise and controllable procedure free results defects, contamination, or inconsistencies. People appreciate the quality and safety of this product and will be consumers that likely are devoted.

Enable your production journey by working with our skilled designers and experts. We're ready to assist you through any challenges and Twin screw extruder machine of your production. Leveraging cutting-edge intelligent get a handle on systems, people provide seamless, remote and valid technical assistance, making sure your production operates efficiently.

GSmach leads the market for Twin screw extruder machine in China, collaborating with renowned international companies such that BASF, Owens Corning, ISOFOAM, Ravago, and various others. Our track record proves our dedication to serving industry management around the world.

Our machines are compliant with international standards for safety and quality offering Twin screw extruder machine. You can save up to 40% as compared to other European suppliers. Our experienced team and multilingual service guarantee both high-quality products and unmatched client service.

We began operations in 2003 and are expert in the growth of polymer extrusion technology. People focus on top of twin-screw extruders we have successfully shipped over Twin screw extruder machine. Our years of suffer from will offer you unfailing support.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy