How Pasta, Plastic or Cereal Is Made

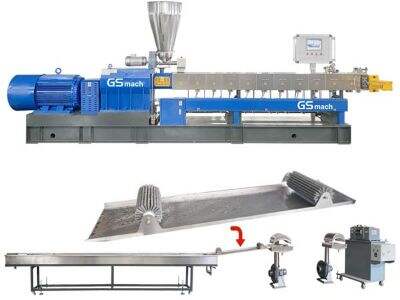

For those of you at home that have ever wondered how pasta, plastic or even their favorite cereal is made you might be interested to learn about twin screw extruder and the fundamental role that screw design plays in making them so efficient. Here at GSmach, we know just how influential screw design can be for twin screw extrusion performance and that is why we wanted to break the concept down.

Importance of Screw Design for Twin Screw Extruder Optimization:

Picture a powerful machine with two giant rotating screws inside of it and you'd have a rough image of what a twin-screw extruder is. There screws are called the heart of the extruder, they are used for mixing and melting and forming raw material that is ultimately made into final products. Screw design is one of the most important aspects for the operation of an extruder. Manufacturers can enhance screw productivity, lower energy consumption, and improve the quality of their products simply by selecting the right screw design carefully.

A study of screw geometry and its effect on material processing in twin screw extruders

The geometry of the screws in a twin-screw extruder is critical for how materials are processed. Additionally, different screw designs can influence material interaction by altering how the material mixes, conveys and melts. For instance, incorporating a certain profile of screw to enhance the material being processed wide surface area may result in better heat transfer and improved mixing efficiency. Understanding how screw design affects material processing enables manufacturers to fine-tune their extruder for brass compounding, achieving this quality product on a routine basis.

Importance of screws elements and configuration for increasing output & productivity:

Besides the flight design, screws in twin screw extruder also play a crucial function to improve output and effectiveness according to their features and arrangements. Manufacturers can customize the extruder to meet their materials and products by including elements such as kneading blocks, mixing elements, or conveying elements into the screw design. When optimized, it can result in time savior, waste reduction and overall best performance of the extruder.

Improving Product Quality and Consistency with Precision Screw Design in Twin Screw Extrusion

Improved Product Quality and Consistency with Precision Screw Design in lab twin screw extruder Manufacturers can minimize discrepancies while avoid shortcomings with their products by taking the time to design the screws correctly so that materials can be mixed, melted, and shaped uniformly. For certain industries like food processing or pharmaceuticals, the precision can be particularly necessary as it can make a tremendous difference between repeatable consistent quality or spoil whole batches.

How the Proper Screw Design Can Help You Get Maximum Throughput While Minimizing Energy Consumption in Twin Screw Extruders

Lastly, if manufacturers select the accurate screw design in a twin-screw extruder, their throughput can be maximized without increasing too much electricity consumption. Manufacturers optimize the screw profile, elements and configurations to maximize the extruder output, while maintaining quality and efficiency. That allows more products to be made in less time with less energy, not just a plus for the environment but for corporate coffers.

This concludes how screws are the most crucial factor to tailor made the performance of twin-screw extruders. Understanding the significance of screw design and its impact on material processing, investigating the relationship between screw geometry and processability, choosing the right types of screws elements and configurations, improving product quality and consistency with accurate screw designing as well as optimizing throughput to conserve energy output. All goes a long way in enabling manufacturers to make their extrusion unit operations more efficient. At GSmach, we pride ourselves on working hard to provide the tools for our clients to meet these objectives & with expert wall cutting-edge technology-literally in co rotating twin screw extruder techniques.

Table of Contents

- How Pasta, Plastic or Cereal Is Made

- Importance of Screw Design for Twin Screw Extruder Optimization:

- A study of screw geometry and its effect on material processing in twin screw extruders

- Importance of screws elements and configuration for increasing output & productivity:

- Improving Product Quality and Consistency with Precision Screw Design in Twin Screw Extrusion

- How the Proper Screw Design Can Help You Get Maximum Throughput While Minimizing Energy Consumption in Twin Screw Extruders