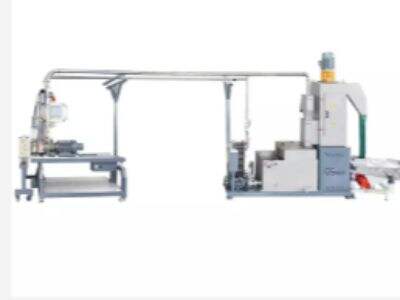

Once you know the nature of different plastics can help you to improve your GSmach pelletizer machine for high efficiency and effective pelletization. Different plastics possess different characteristics that can change the way they are injection molded so it is important to know the properties of each type while using your machine.

The best quality pellets

The best quality pellets are produced from suitable pelletizing of the process and setup parameters turn out to be very essential for getting the optimized benefits out of your Pelletizer. Setting temperature, speed and pressure correctly will allow you to run your pelletising machine at the best it can manage for producing pellets that are suitable to your specification.

The type of pelletizer die you pick

The type of pelletizer die you pick will be critical, since it determines the size and shape of your pellets. Die designs vary based on the type of plastic used (type of Plastic) to comply with your desired specifications for Pellets. Making the right choice with your material, you can improve the pellet quality, and in turn have a higher-quality end product.

Proper Cleaning and Maintenance of Your Pelletizer Machine

With regular maintenance, like oiling and removing loose material from the pelletizer, you can help avoid breakdowns and will assist in ensuring that it lasts longer. Dull knives are a common issue for any type of computer used for cutting or engraving, and most of the time dulling is not because of material wear but rather contamination degradation of the materials experiencing friction from both sides. You can ensure that it remains as such with a maintenance schedule which includes keeping your pellet making machine clean.

troubleshooting common pelletizing problems for different types of polymers

By troubleshooting common pelletizing problems for different types of polymers, you can more rapidly diagnose the problem and rectify it so your down time is kept to a minimum and your pellets are always in specification. Knowing what to look for in common pelletizing problems and causes will allow you to troubleshoot, so damp, dry or virgin plastics can be run through the pelletizer.

Finally, optimizing your pelletizer machine for various plastics includes the need to know their properties, parameters adjustment in shearing plastics molding process ensuring there is proper and balance die type for your pelletizer, maintenance tips and routine cleaning of the pellet maker machine and how to troubleshoot any common issues with allowing the smooth process of pelleting. Following these rules will help you get the most from your pelletizer and ensure high-quality pellets on an ongoing basis.