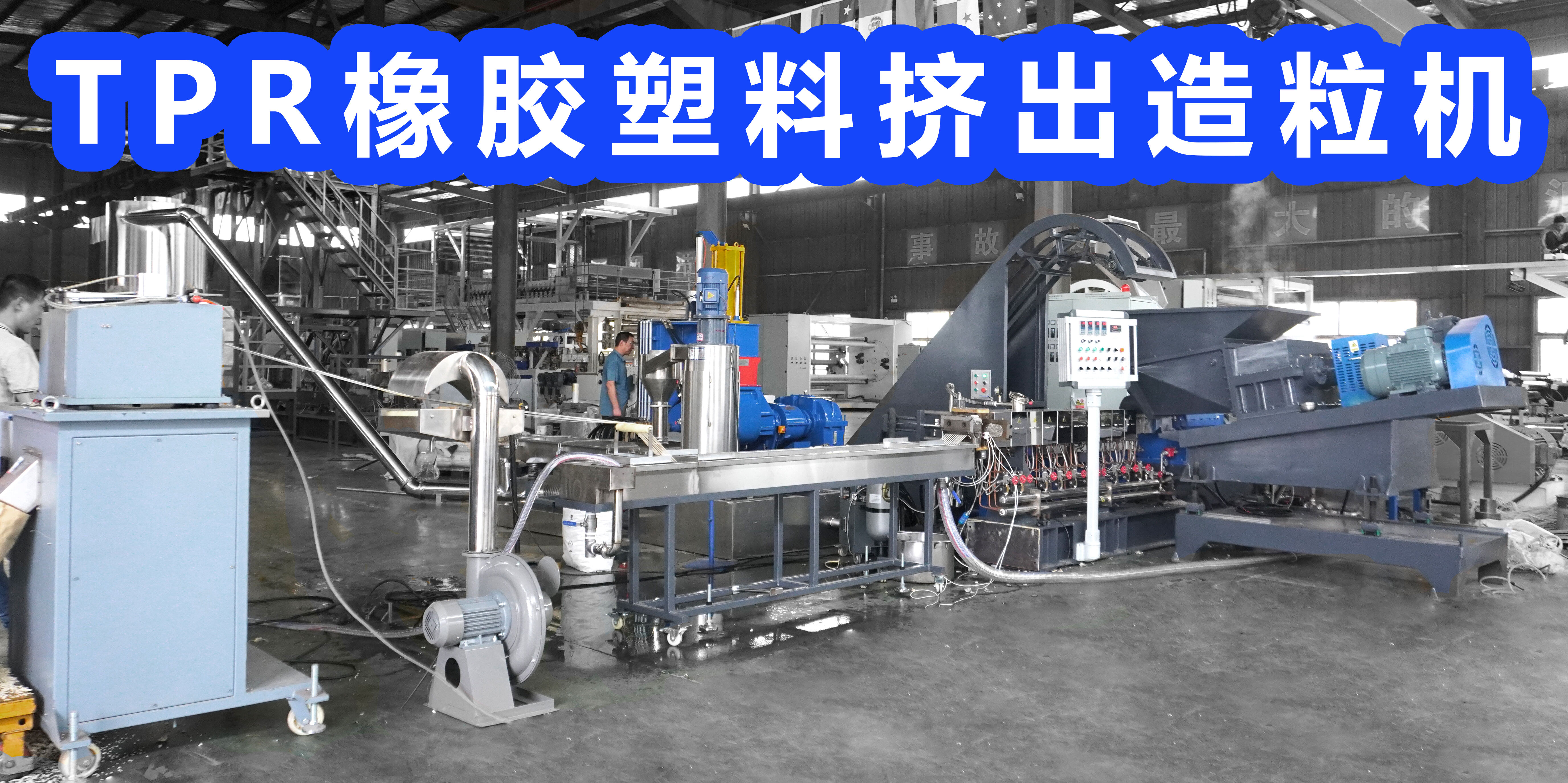

TPR Rubber Compound Extrusion Line

Nanjing GSmach Equipment Co., Ltd. is a factory established in 2013, we GSmach has been dedicated to producing plastic machinery, including twin-screw extruder, compactor, biodegradable pelletizing/sheet production line, plastic sheet machine and so on. Today, I will share with you a customer's machine case.

This customer is from Thailand and engaged in rubber related business, now they want to add some plastic materials into rubber compound to get new products and expand their market. Since their main raw material is rubber compound with big lumps and strong viscosity, and it also needs to be mixed with PP particles, so considering these factors, I suggested them to use a mixer to let the raw material be completely mixed, heated and melted.

The complete line is equipped with a 5L Kneader, a Conveyor, a Twin Screw Force Feeder and a GS35 Twin Screw Extruder with a Water Drawbar Pelletizing System. The line can produce up to 30-50 kilograms per hour, which is sufficient for customers who need to conduct laboratory-scale market research.

During the production process, the temperature and time of the kneader are first set and then the rubber and polypropylene pellets are fed directly into the kneader according to the recipe. Because of the high melting point of PP, the temperature will reach about 160-200 degrees. Then we get a fluffy, dough-like melted mixture, which means we've succeeded. This step is crucial in the whole production process. If the ingredients are not completely melted and mixed in the first step, then we will not get good finished pellets.

The mixture will then be transferred from the conveyor and twin screw force feeder to the twin screw extruder. Here also single screw extruder can be used instead of twin screw extruder. The advantage of a twin-screw extruder is that the mixture can be mixed and plasticized twice. We at GS-Mach usually have five types of pelletizing systems, namely water-cooled drawbar pelletizing systems, air-cooled hot-cut pelletizing systems, water ring cutting systems, air-cooled drawbar cutting systems and underwater pelletizing systems. Since the mixture was very viscous and the customer wanted to invest less in this machine, we decided to use the water slat pelletizing system and succeeded in obtaining good finished pellets.

Of course, we had some problems during the production process, but with the help of our technicians we were able to overcome them by adjusting the recipe. Therefore, you can always trust GS-mach's competence and machine quality. If you also have similar materials or have an idea to make the above mentioned pellets, we, GS-mach, are always ready to welcome you.