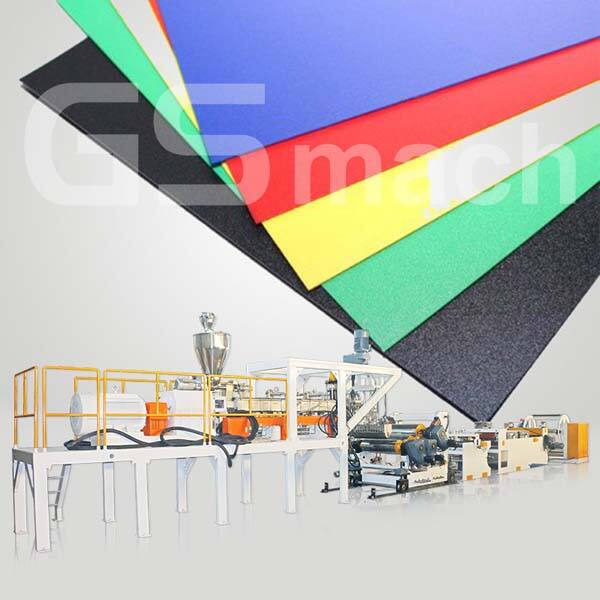

Sheet Extruder: Making Sheets with Ease.

Are you currently sick and tired of purchasing expensive Sheets of plastic for your tasks as packaging specifications? Search no further, because a Sheet Extruder is here to help, as well as the GSmach's cast film extruder. Sheet Extruders are machines that will build thin Sheets of plastic for different industrial and commercial applications. Let us plunge to the advantages, innovations, safety features, and a lot more of this unique technology.

Sheet Extruders as well as GSmach's twin screw extruder machine offer most advantages, such as:

1. Cost discount: By having your own Sheet Extruder, you will cut costs on purchasing pre-fabricated Sheets.

2. Customizable: You are able to personalize the depth, colors, and texture of the Sheet according to your requirements.

3. Consistency: Unlike handmade Sheets, Sheet Extruders can offer persistence into the quality of the Sheets produced.

Sheet Extruders went with numerous innovations over time, creating them better and user-friendly, the same as roller laminating machine innovated by GSmach. A number of the latest innovation include:

1. Automated settings: Modern-day Sheet Extruders come prepared with computerized settings that will monitor and adjust multiple aspects, for instance the speed and temperature associated with process.

2. Versatile designs: Sheet Extruders now can make long or short Sheets, with respect to the venture requires.

3. Energy-efficient: The modern Sheet Extruder is built to eat much less power, reducing functional prices although protecting the environmental surroundings.

Safety ought to be the main concern once working with any heavy machinery like a Sheet Extruder, similar to the GSmach's product like spiral kneader. The next safety features can be found in most Sheet Extruders:

1. Emergency Stop Button: A crisis end switch is positioned near to the operator's desk which will power down the machine in the event of an urgent situation.

2. Safety Guards: Safety guards are positioned round the machine to avoid employees from getting too near to moving parts regarding the machine.

3. Lockout tag out system: This system means that no unauthorized workers may start as run the machine.

Making use of a Sheet Extruder is relatively simple; nevertheless, you will need to stick to the right actions to attain the best outcome, just like the extruder pelletizer built by GSmach. Right here is the overall process:

1. Create the raw materials: Plastic pellets is first put in the hopper. You may want to incorporate colors and more chemicals to the pellets.

2. The Extrusion Process: The Extruder melts the pellets and pushes them by way of a die that shapes the melted plastic.

3. Cooling and Cutting: Following the plastic is shaped, it is cooled, and the Sheets is cut in to the desired size.

Established in 2003, we focus on polymer extrusion machines and process Sheet extruder. We've delivered a lot more than 2,500 twin-screw devices. Our years of experience will provide you with unwavering support.

Our machines are designed to meet international safety and Sheet extruder. We offering economical solutions. Save as much as 40per cent compared to rivals. European suppliers. Your talented team and multilingual service ensure both satisfied products and unparalleled customer care.

The team of experts and engineers will likely get there to assist you in your Sheet extruder. We're prepared to simply services you overcome obstacles and improve your production performance. Currently remote and seamless technical support with cutting-edge, smart techniques.

GSmach is the market leader in Asia for extruded Sheet extruder and is collaborating internationally with world-class firms including BASF, Owens Corning ISOFOAM Ravago and many more. Our track report demonstrates our dedication to serving leaders in the industry around their globe.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy