Advantages of Twin Extruder Machine.

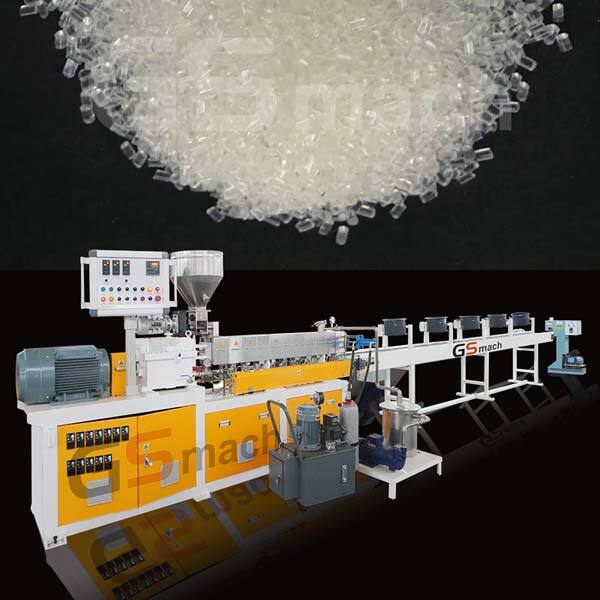

It was widely utilized for creating different kinds of products from vinyl, rubber, and other materials. The GSmach twin extruder machine is designed to have two screws that really work together to produce a homogeneous blend of materials.Twin extruder machine is versatile something within the manufacturing markets. There were a few benefits of using a twin extruder machine, such as:

1. High effectiveness – Compared to, twin extruder machines being single-screw extruders an increased production rate, what this means is they are able to create more material in a shorter time.

2. Constant quality – The materials are blended uniformly, causing a regular quality of completed product.

3. Flexibility – twin extruder machines are often modified to generate several types of products, making them highly versatile.

One of the innovations may be the introduction of computerized controls, which permits for exact control over the extrusion process. Also, twin extruder machines are now actually made out of best materials, supplying better durability. They will have undergone a couple of innovations to generate them more efficient, safer, and user-friendly. GSmach Twin extruder machines need come an easy method that have become long their inception.

As an example, they will have installed safety interlocks to avoid injuries when opening the machine adjusting the screws. Also, they use state-of-the-art software that may identify any anomalies and shut down the machine automatically to avoid any danger which was potential. GSmach have taken significant measures make sure that these machines are safe to use. Safety is simply a critical aspect of manufacturing process, and twin extruder machines as well as the twin screw extruder machine are not any exception.

Twin extruder machines can be utilized in a variety of industries, including plastic, plastic, items, and pharmaceuticals. The mix is then forced out through a die and cooled to create the final item. GSmach been employed to come up with differing types of products, such as pipes, tubing, films like cast film line, and coatings. The process involves introducing the raw materials to the twin extruder machine, which then melts and blends the materials together to make a homogenous mix.

First, load the materials which are raw the apparatus's hopper. Using a GSmach twin extruder machine comparable with film extruder machine isn't way too hard, however it requires some skills that could be technical effortlessly. To make use of the equipment, you have got to abide by the maker's guidelines meticulously. The operator should monitor the task continually and also make any important changes to ensure a quality this is certainly regular of product. Then, turn on the apparatus and set the warmth that's needed is extrusion speed.

GSmach is the leader in China for extruded Twin extruder machine working internationally with well-known firms including BASF, Owens Corning ISOFOAM Ravago and many more. The record of success demonstrates our dedication to quality when servicing global field top players.

We are founded in 2003 and are specialized in the process of Twin extruder machine. We concentrate on twin-screw extruders, people have efficiently delivered over 2500 models. Our encounter and expertise provides you with unmatched assistance.

Your skilled engineers and experts are available to greatly help you along your way. We're ready towards Twin extruder machine you overcome challenges and optimize your production effectiveness. We provide remote and seamless technical support using cutting-edge smart techniques.

Our equipment is in line with international standards of safety and quality offering affordable solutions. Enjoy significant savings, as high as 40% in contrast in order to other European suppliers. Our multilingual team and expert employee will ensure that customers receive the Twin extruder machine and service.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy