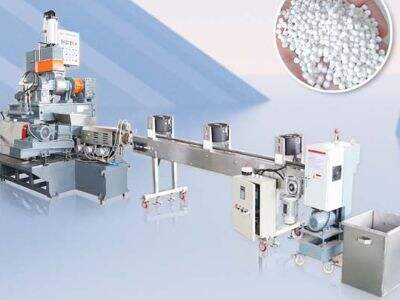

How a Twin Screw Extruder Enhances Plastic Pelletizing Efficiency

Twin Screw Extruder is a pretty amazing machine, that transforms the process of turning plastic material into pellets easier and faster. You ever ask yourself how do plastic pellets made? Visualise a large machine containing two screws that revolve and transmit the plastic material. It is named Twin Screw Extruder an substantively of make plastic pellets efficiency.

Twin screw extruder has a higher plastic raw materials throughput, and the production efficiency is correspondingly improved.

As a result, the production capacity of the following pelletising machine will be improved obviously and more plastic products can be produced in much less time based on this revelation, which goes without saying that it makes GSmach Company have advantage to make production fast with high productivity. The inside of the extruder has two screws that turn in tandem, moving and kneading the plastic as it goes through the machine, making it work faster.

Dual screws of the extruder ensure homogeneously dispersed additives and blending which leads to uniform pellets.

Additives are materials that can be mixed with the base plastic to modify properties such as color or strength. Incorporating this type of grinder prior to extrusion is that from the twin screw extruder which will distribute these additives into the mass of plastic, the final product pellets with same quality every time.

The design of the extruder enables to efficiently degas trapped air and moisture in the plastic which results in an improved quality final product.

In the pelleting process, air and water may become trapped in the steel material which can crash the quality of the finish effect. The screw twin extruder machine design booted the trapped gases and moisture out of the system to guarantee a dazzling specification of plastic pellets.

Twin screw extruders are able to process a wide variety of materials and additives, making them flexible for various pelletizing demands. From hard plastics, soft plastics and also special additives the twin screw extruder is capable of processing it. The greater flexibility in use enables a manufacturer like GSmach has to do different projects with one machines for plastic pelletizing which is an advantage to more efficient and economic production.

Table of Contents

- How a Twin Screw Extruder Enhances Plastic Pelletizing Efficiency

- Twin screw extruder has a higher plastic raw materials throughput, and the production efficiency is correspondingly improved.

- Dual screws of the extruder ensure homogeneously dispersed additives and blending which leads to uniform pellets.

- The design of the extruder enables to efficiently degas trapped air and moisture in the plastic which results in an improved quality final product.