This extrusion laminating machine using the resin , such as

LDPE, HDPE, PP, EVA, etc., as raw material, it processes by melting

the plastic for extruding form the T-die mould and finally laminating

with the base material, this type of machine has been widely used for the

lamination of substrates such as paper, non-woven fabric, woven fabric, aluminum foil, BOPP film etc.

the finished product is famous for its high fastness, uniformity of

thickness and high sealed capability. All these have contribute of make

this type of machine become one of the most popular and valuable

extrusion laminating machines in domestic market and abroad.

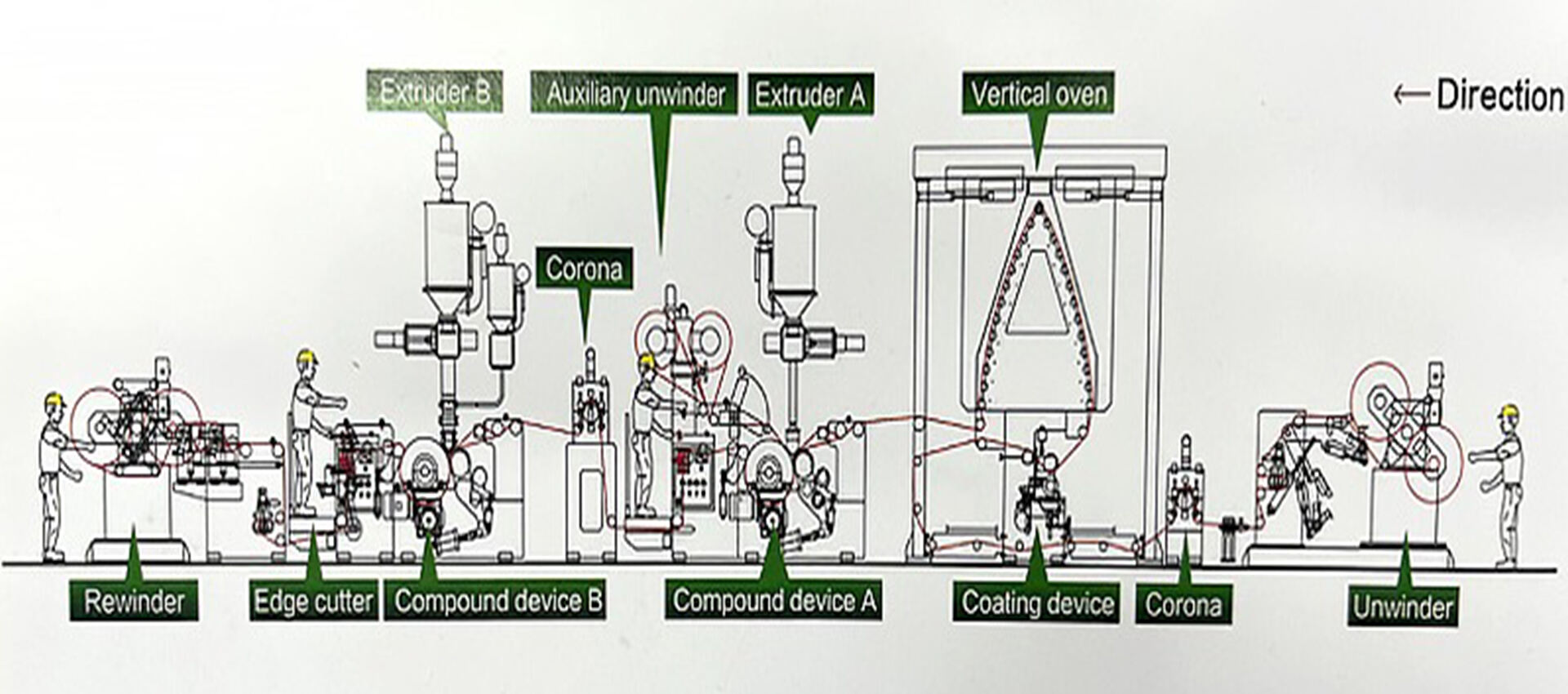

1.Double Sided Color Printing Packaging Extrusion Laminating Machine

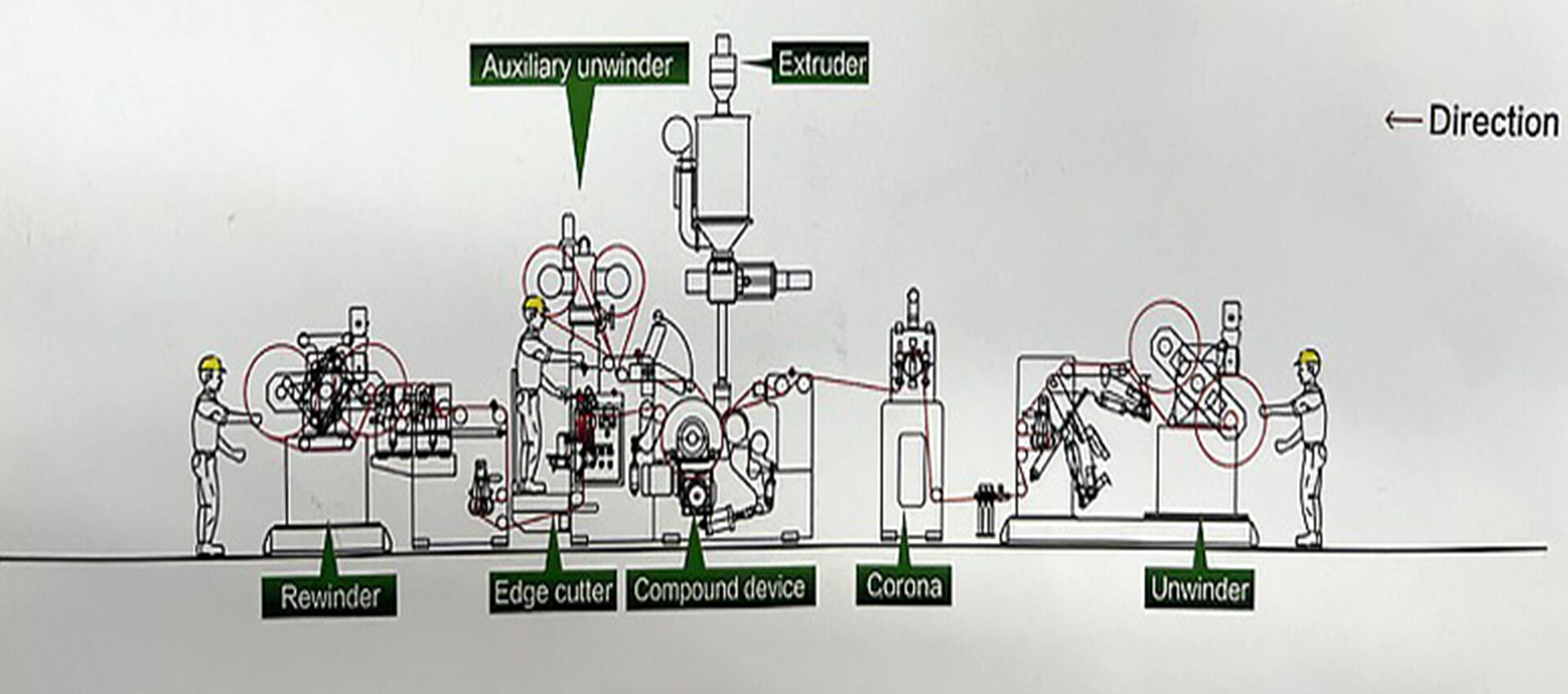

2.Single Sided Color Printing Packaging Extrusion Laminating Machine

Color Printing Packaging Extrusion Laminating Machine

Double Sided Color Printing Packaging Extrusion Laminating Machine

Single Sided Color Printing Packaging Extrusion Laminating Machine

Technical parameters

| Machine width | 1200/1400/1700/2200/2500mm |

| Effective width | 1100/1300/1600/2100/2400mm |

| Machine speed | 200~250m/min |

| Screw diameter | LD-80mm to LD-115mm |

| Extruder output | 180kg/h, 200kg/h, 300kg/h or 400kg/h |

| Used resins | Coated resins like LDPE/LLDPE/PP/EVA/EAA |

| Coating thickness | 5~45um |

| Max diameter | Unwinder&rewinder:φ800mm |

| Sandwich diameter | Max φ600mm |

| Sandwich material | CPE/CPP/PET/Aluminium foils |

| Basic material | Aluminium foil/Non-woven fabric/Metalized film BOPP/BOPET/BOPA, etc(10-200gsm) |

| Dimension(L*W*H) | Mono extrusion:11.65x(9.5~14)x3.8m |

Main Features

Two original paper rolls can be installed at the same time on the shaftless unwinder.

Auto-splicing is controlled by computer and can be done without stopping the line.

Web-guide device ensures that the paper/paper board passes uniformly and neatly.

Bead cutter for edge trimming.

Corona treatment on the surface of paper is to increase the peeling strength of PE and paper.

Rewinder consists of rewinding stand, tension control system, splicing device and towing device.

Tension control system is to ensure the constant tension of rewinding.

Applications:

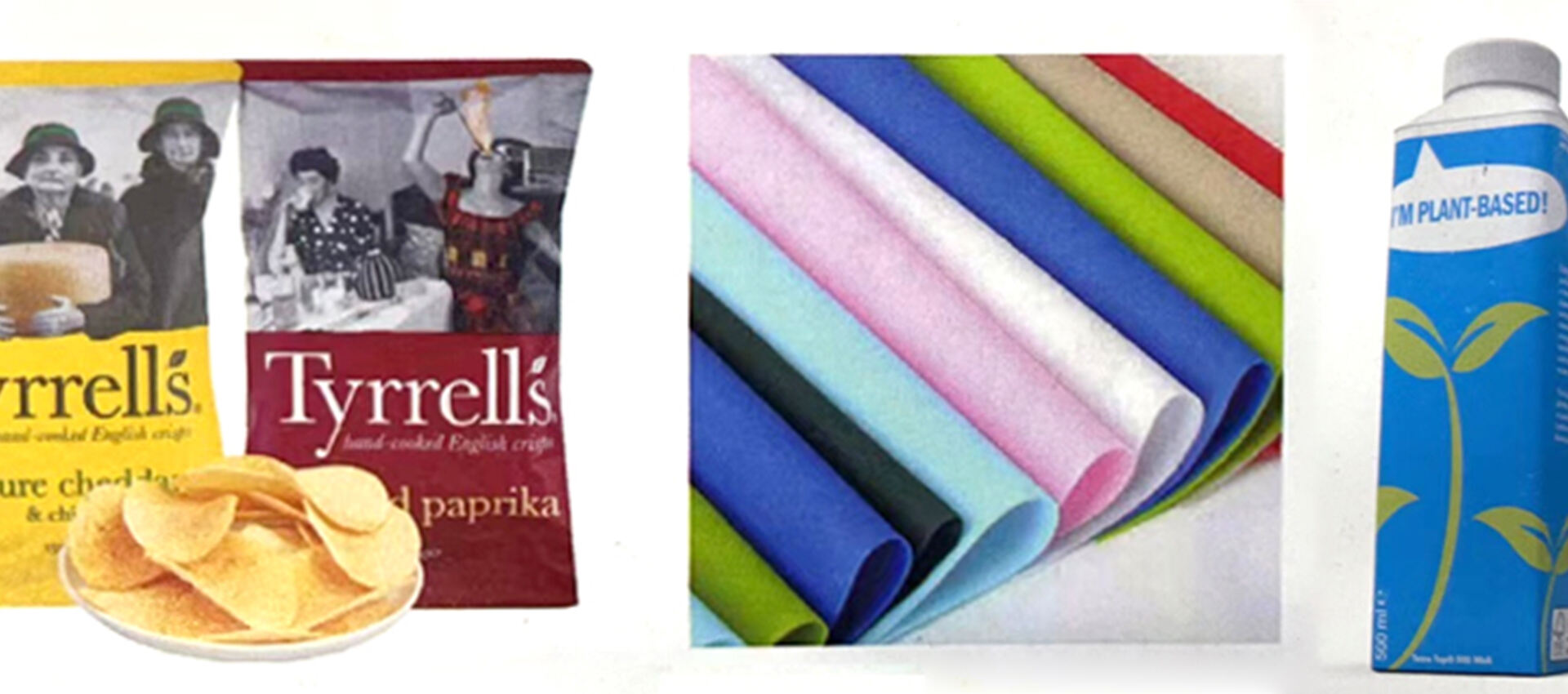

Food packaging materials

liquid packaging materials

Non-woven fabrics compound with color printing films / woven fabrics compound with aluminium foils / aluminum-plastic compound

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy