GSmach designs and manufactures extrusion laminating/coating lines on the strength of a thorough expertise in the co-extrusion of special polymers - customized and modular layout to meet the demand for special products; - chill-roll unit with precise temperature control - rapid cooling system - special winders and unwinders suitable for any final application.

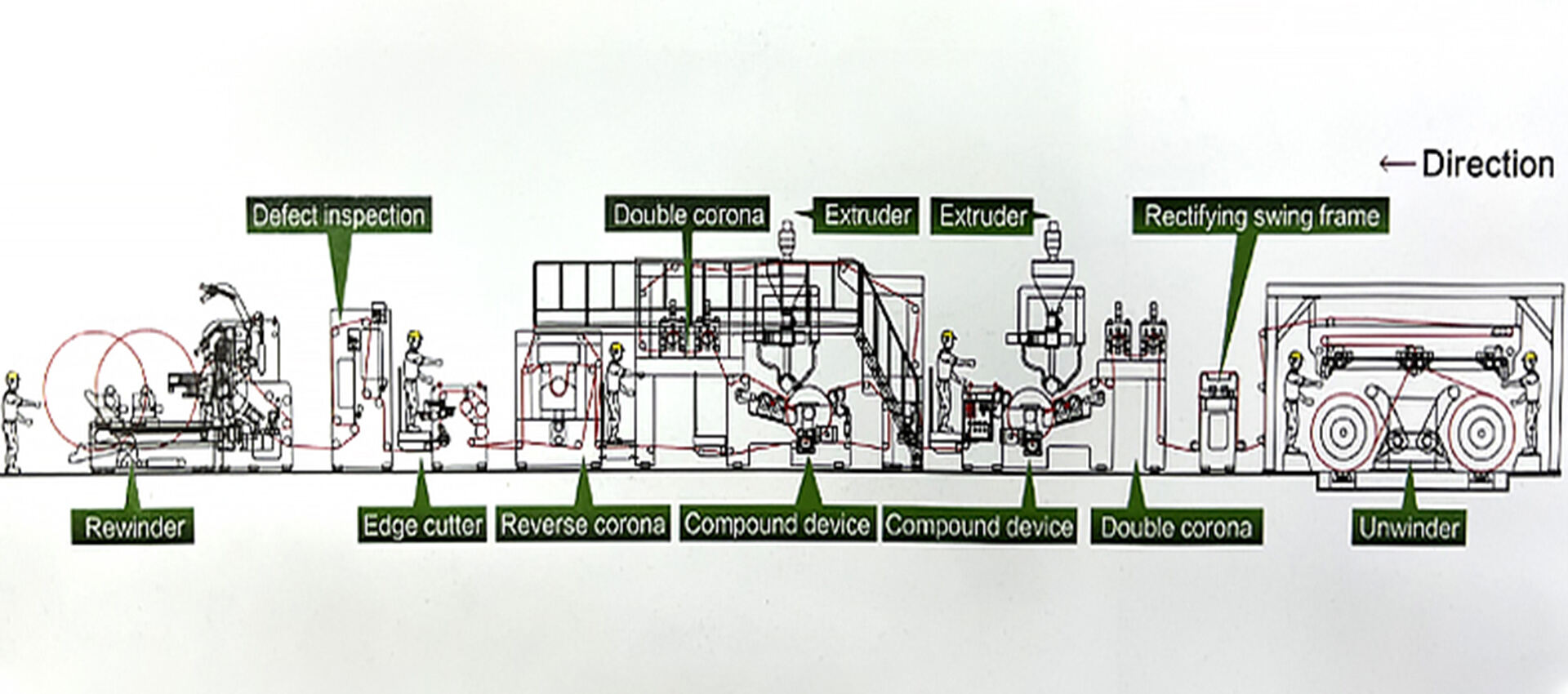

1.Double Sided Cup Paper Extrusion Laminating Machine

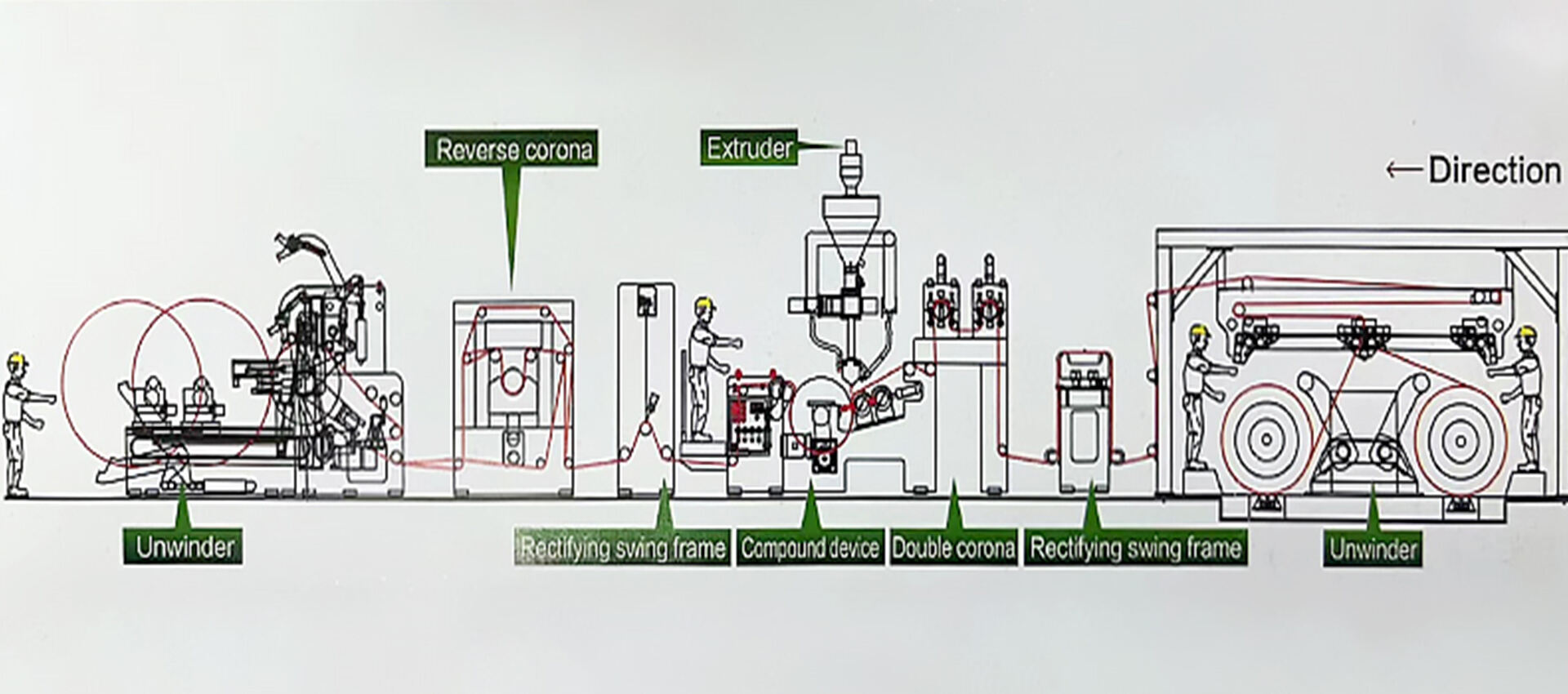

2.Single Sided Cup Paper Extrusion Laminating Machine

GSmach extrusion and co-extrusion units at the forefront of technology, boasting a high manufacturing quality with components suitable for processing also corrosive polymers. we has focused on high performance extruders with special screw design for a wide range of materials like LDPE, SURLYN, EVA, EAA, PP, with customized solutions including different layers, sizes and die widths.

Cup Paper Extrusion Laminating Machine

Double Sided Cup Paper Extrusion Laminating Machine

Single Sided Cup Paper Extrusion Laminating Machine

Technical parameters

| Machine width | 1200/1400/1700mm |

| Effective width | Max 1100/1300/1600mm |

| Machine speed | 300m/min |

| Screw diameter | LD-100mm/LD-115mm |

| Extruder output | Max 400kg/h or 550kg/h |

| Used resins | Coated resins like LDPE/PP/PBS/PLA |

| Coating thickness | 8-45μm |

| Maxdiameter | Unwinder:Φ1500mm;Rewinder:Ф1800mm |

| Basic mnaterial | Paper(100-400gsm) |

| Dimension(L*W*H) | Double:30.7*(9.5-11)*3.8m |

| Single:21.5*(9.5-11)*3.8m |

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy