GSmach designs and manufactures extrusion laminating/coating

lines on the strength of a thorough expertise in the co-extrusion

of special polymers - customized and modular layout to meet the

demand for special products;

- chill-roll unit with precise temperature control - rapid cooling

system - special winders and unwinders suitable for any final application.

Laminating Film Extrusion Laminating Machine

Laminating Film Extrusion Laminating Machine

Technical parameters

| Machine width | 1200mm,1550mm |

| Effective width | Max1100mm,1400mm |

| Machine speed | 150m/min |

| Screw diameter | Φ100mm,Φ115mm |

| Extruder output | Max 250kg/h ,300kg/h |

| Resins | EVA |

| Coating thickness | 8-45μm |

| Max unwinder and rewinder diameter | Φ800mm |

| Basic material | PET film |

| Dimension(L*W*H) | 19.5*(9.5~12)*3.8m |

Main constructions:

1) Double Shaft-less paper roll stands suitable for 3-6 inch paper core,automatic lift ,easier operation .

2) Auto splicer device realize paper in 150-300 m/min speed exchange without decrease machine line speed

3) Ultrasonic type EPC system,makes frequent replacement materials operation more simple

4) Hydraulic lamination structure design , can make coating thinner and firm .

5) Trimming device make the finished coated paper rolls even

6)Special cutting knife and rewinder design makes high speed rewinding shafts exchange possible.

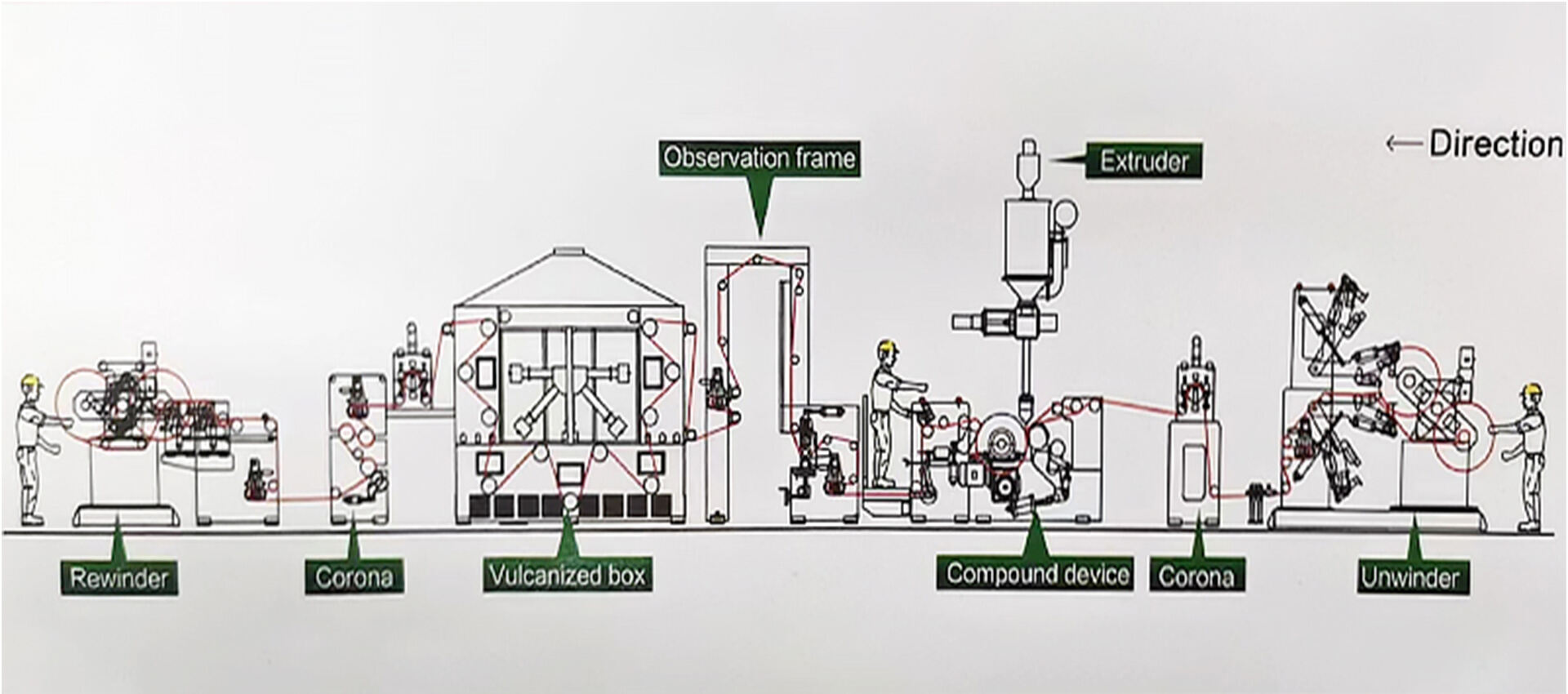

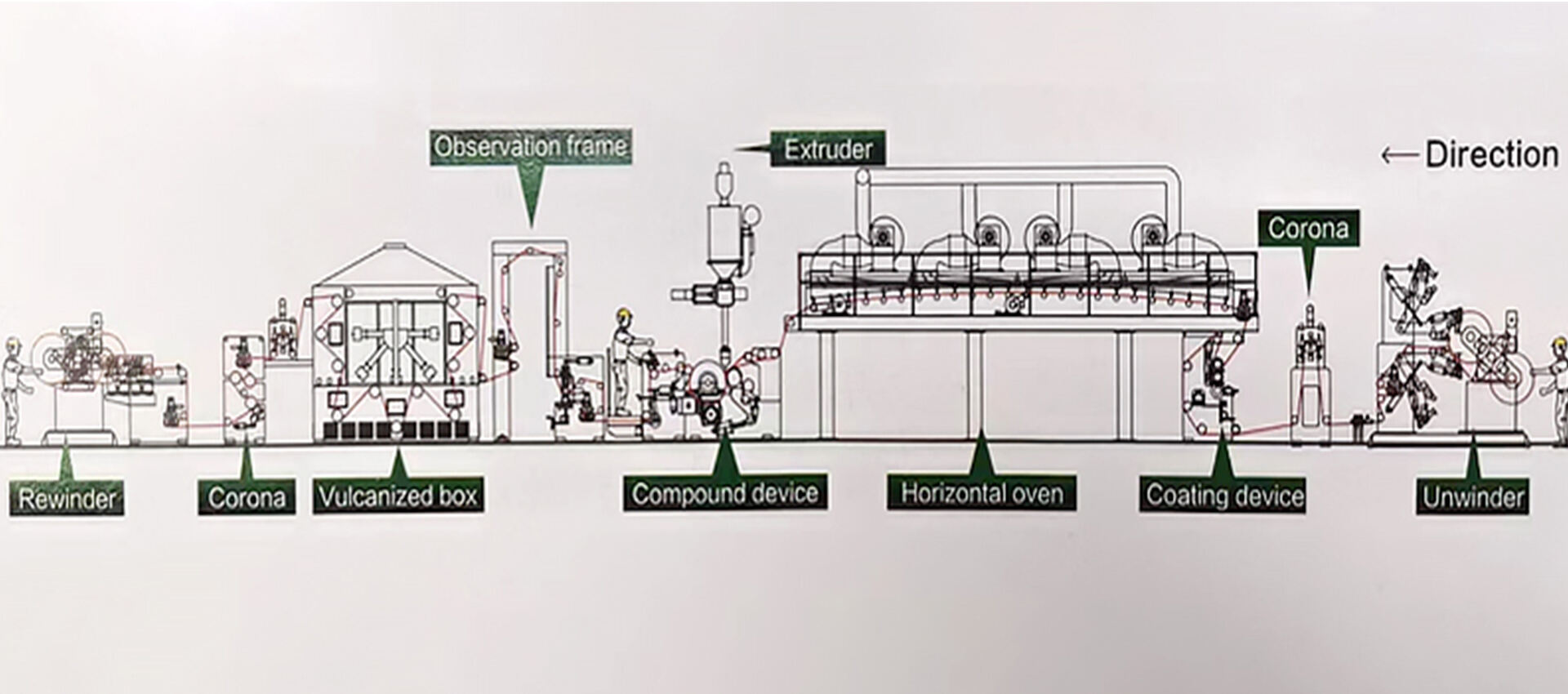

Compound machine

The coumpound device consist of cooling roller, silicone rubber pressure roller, back-up roller, discharge roller, trimming deflashing device, wheelwork pneumatic device and some other devices. It is used to combine melted sheet film with basic materials and is the key device of extrusion lamination or extrusion coating. Its main functions are composite, cooling and shaping.

Its production line is equipped with external hard chromium plating and steel rollers with double-deck clamp cover auger-type screw channel. the clamp cover of screw channel is filled witth cooling water to take away the heat of melted thin film so that composite thin film can get a great result in cooling shaping, and this greatly improves the fastness, smoothness and external beauty of composite.

Extruder

Extrusion machine is the key of extrusion laminating equipment and consists of screw,barrel and transmission mechanism. It has the functions of delivering, fusing, measuring, mulling of solid materials and delivering melt.

Laiyi's self-developed screw is high-speed,high-cutting and high-mixing, and has many advantages like large extrusion output, low heat, small changes in extrusion pressure, no extrusion of non melt resins, no bubbles and energy saving.

The extruder can equip newly designed auto-lifting function that can adjust air gap height at any time to adjusting the most suitable air gap height according to line speed.

Double station unwinder:

It applies to multiple materials and has a wide range of us.

It can automatically change rolls without stopping machine or reduce speed.

It has one-button and no-button type operation, is simple and conveniet.

It occupies small area, can save the production spaces.

Double station rewinder:

It can automatically change rolls without stopping machine or reducing speed.

It applies to multiple materials and has a wide range of uses, has different way to control tension of different material.

It uses suspension type press roller to rewind, the tension of multiple materials can be controlled to guarantee the smooth and beauty of the production surface.

Applications:

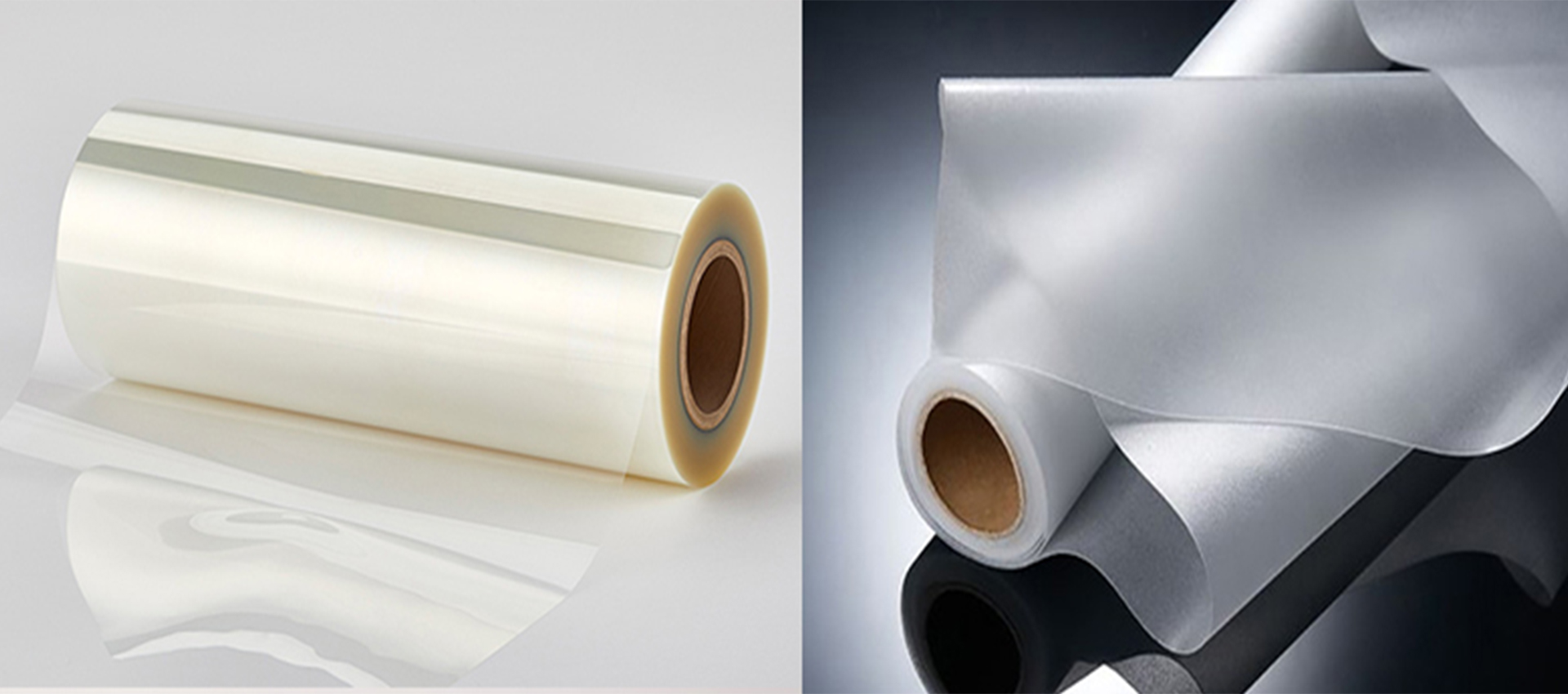

Protective laminating film(PET/EVA)

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy