PVDF and ETFE films are fluorine-based plastic films that are prone to occur thermal decomposition during heat treatment process, which can lead to corrosion of processing equipment and molds.

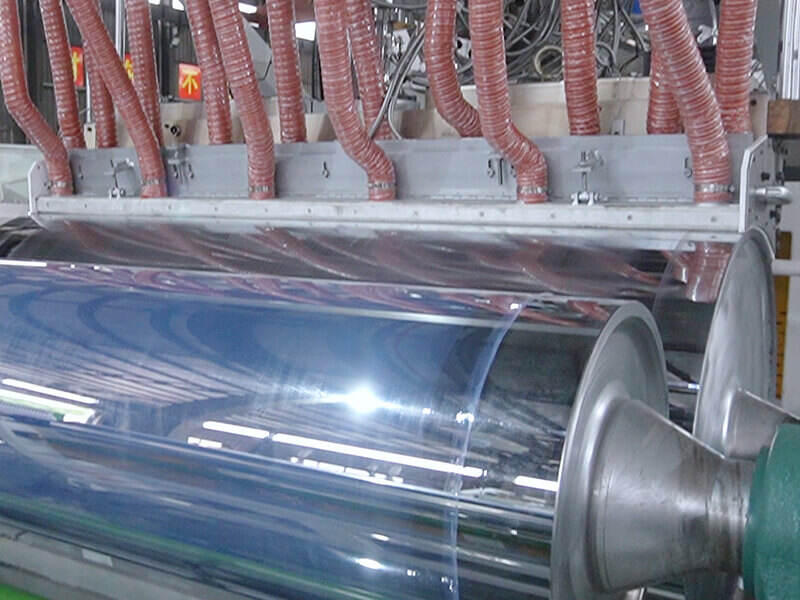

Given this situation, GSmach Machinery PVDF/ETFE Cast Film Line is thoughtfully designed with specific extrusion processes that are different from general thermoplastic processing equipment and processes.

This extrusion line is typically used for manufacturing fluoropolymer films such as PVDF and ETFE films.

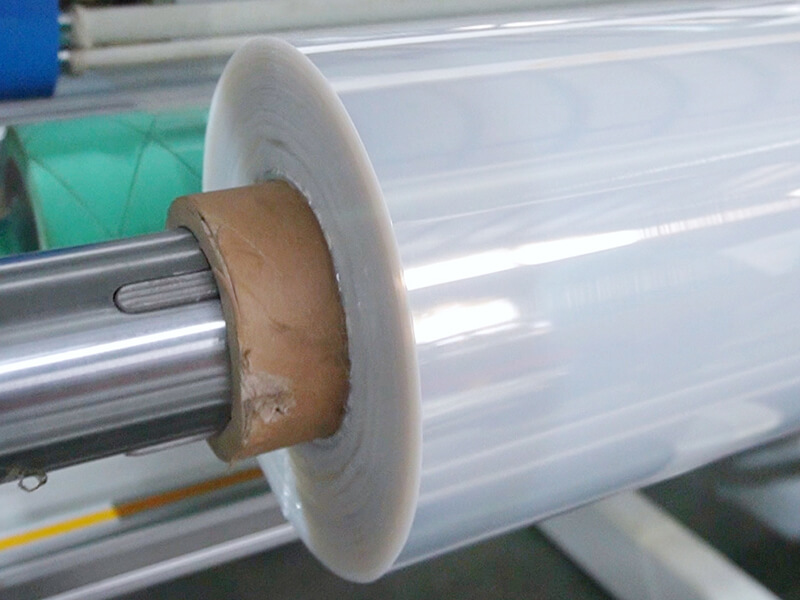

Through this specially designed cast film extrusion line, the produced PVDF films have a wide range of applications, e.g.

PVDF film for PV panel backsheet protection, PVDF water filtration membrane, PVDF protective film for outdoor applications, etc.

Features

1.Extruder is made of high-temperature corrosion resistant steel to ensure smooth extrusion process of thermoplastic;

2.Due to the technical cooperation with domestic universities, the extrusion screw structure and die structure are exceptionally designed taking into account the unique properties of fluorine materials, combined with advanced forming and winding processes to accomplish large-scale production of fluoropolymer films in a rational manner;

3.High-end configuration, rationalized design and PLC control with touch screen guarantee an easy-to-operation and safe production process;

4.A variety of specifications are available to fulfill customers’ requirements;

Applications

1.PVDF film for PV panel backsheet protection

2.ETFE transparent film, thickness less than 0.20mm

3.ETFE film for cladding applications, such as roofing and façade

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy