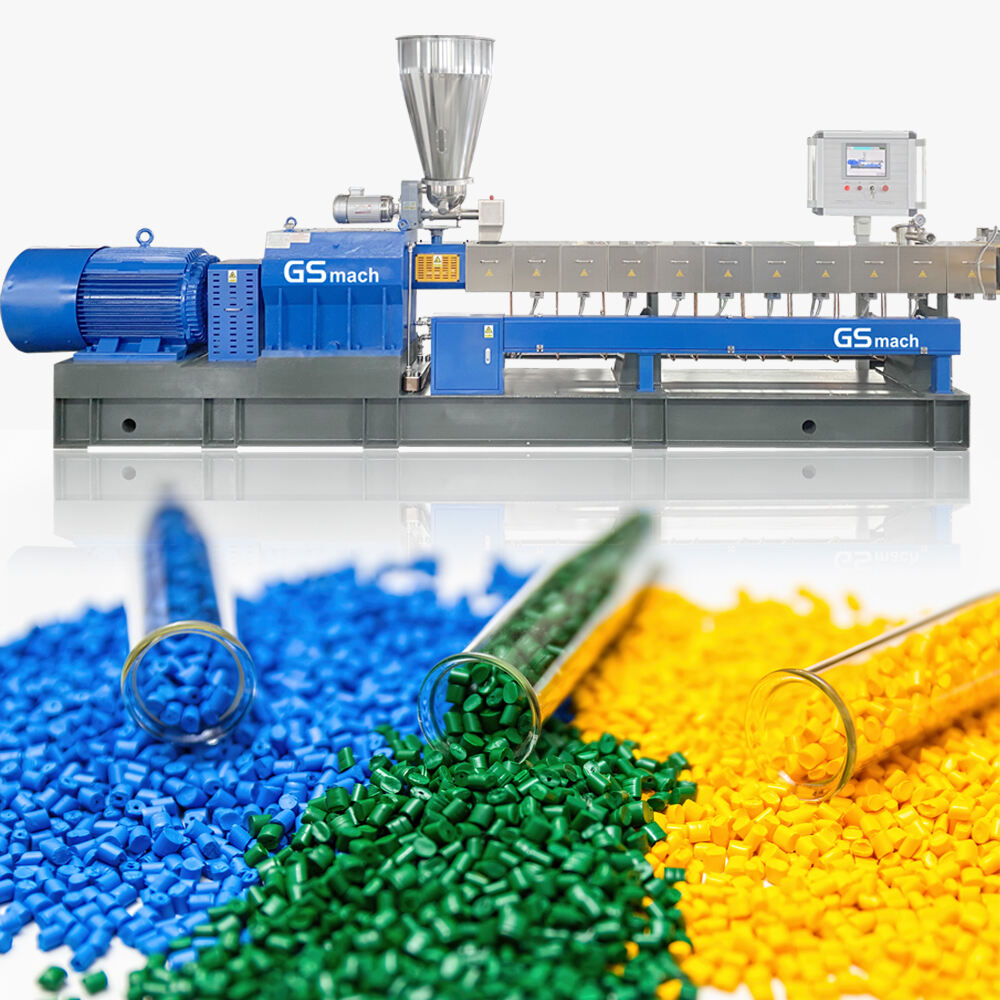

Twin screw extrusion lines are key machines for production. They help to mix and shape materials, such as plastic and food. There are a lot of factors that can influence how well these machines work. By knowing that you can help companies (for instance GSmach) make their extrusion lines better. It is important to examine how these variables can affect machine performance and the quality of products produced. Knowing the worst, organizations can put in to place measures to ensure that their extrusion lines will be productive with as little waste as possible.

What are Some of the Common Usage Problems Faced by Twin Screw Extrusion Lines in the Industry?

A few problems when we use twin screw extrusion machine happening in common. One major issue is temperature. When the machine is too hot, or when it’s too cold, it can screw up how the materials bind. For instance, if it’s too cold outside, the plastic might not melt properly. This can lead to clogs and slow production. Another problem is the velocity of the screws. Screwing the screws too fast can result in uneven mixing. On the other hand, they risk being spun too slow to mix their materials. It’s like if you make a smoothie; just don’t blend it through enough and you still have hunks in there.

The material used being another issue. Certain materials require other circumstances to function optimally. The new material could give a factory that is mixing in it without changing its settings problems. We’ll for instance, if a company normally uses one form of plastic, and then tries out another without reprogramming the machine, well that’s when you don’t get those cakes just right. This can result in an inferior product and waste of material.

Maintenance is also very important. If the machine isn’t cleaned consistently, or has worn out parts, it could break down. These problems can be avoided through regular checks. Monitoring the machines keeps problems from becoming big ones when they are caught. GSmach understands that the maintenance is necessary to keep extrusion lines working in a good condition. It is the responsibility of factory operators to keep an eye on these problems and implement changes where necessary.

Where to Purchase Professional Twin Screw Extrusion Lines at Wholesale Price?

If you are in the market for high quality twin screw extrusion lines, GSmach is an excellent choice! They have a series of machines that are made for different applications in the industry. You might find it worth it to check their website and the different extrusion lines they offer. It’s also nice to see reviews and testimonials from other customers. This can provide a sense of how well the machines are and whether they are worth it.

Alternatively, you could try trade shows and industry events. These events give you a chance to see the machines in action and talk to the experts who made them. You can inquire and knowledge on the newest in extrusion technology. Such personal contact also may enable you to Plus, you may just score some special pricing or discounts at these events.

You can also get in touch with GSmach via local agents. They usually have a variety of machines and can advise you on which type will work best for your necessities. And then there is local support from distributors, if available, which is a significant plus. They can help you with installation and upkeep so your new equipment will work as smoothly as it should.

Last, check out web markets focused on industrial equipment. These services usually have multiple tiers at different price points. Make sure to check, though the sellers your trust may have returned policy. Purchasing machinery requires purchasing from someone you can trust.

Selecting the proper twin screw extruder line is highly critical to your production requirements. Coupled with GSmach’s high quality machines and service, we’ll help you find the right machine that will empower your business to succeed.

Which Maintenance Habits will help to Prolong the Lifetime of a Twin Screw Extrusion Line?

Caring for your twin single screw extruder line is crucial if you want it to last longer. Routine maintenance can help keep everything running smoothly, and thus less chance for big problems down the line. Cleaning the machine regularly And there are a couple of key practices for that. Accumulated dust and residual materials can accumulate and lead to faster wear on parts. You can avoid such problems by cleaning the machine frequently. Screws and barrels need check for wear; this is also another major maintenance every operator should do. These are important parts of the machine, as they mix and push materials through it. If damaged, the entire process can be delayed or even derailed. GSmach suggests that, to maintain better machine condition, screws and barrels which are non-durable should be replaced as soon as possible.

Do not forget to oil the machine. Lubrication reduces friction that can cause parts to heat up and break down over time. A high quality lubricant, recommended by GSmach and applied regularly can significantly affect performance. Operators should also monitor the temperature settings. Ambient temperature too high or too low can influence the processed material and production quality. Another way to prevent this is by regularly adjusting and checking the settings.

Lastly, the operator and maintenance personnel need to be properly trained on how to run the twin screw extrusion line. Well-trained workers can spot problems early, then fix them correctly. GSMach provides training for the workers to understand how to operate the machine. Due to the cleaning, lubrication and maintenance, everyone will work together to let the twin screw extrusion line survive for a rather long time and quality products be received.

Who's Pushing the Envelope on Success with Twin Screw Extrusion Technology?

The second-generation twin-screw extrusion technology is under rapid development and constant improvement. There are new inventions that are making these devices more efficient and user friendly. The use of sophisticated sensors is a promising possibility. The machine can be monitored by these sensors in real-time. They inspect for temperature, pressure and the speed of the screws. Armed with this knowledge, operators can make step-changes to become more efficient. GSmach is a pioneer in this technology and assists operators in making smart machines helping them to keep everything running.

Another advancement has been the introduction of new materials for screws and barrels. These materials are more durable and less vulnerable to wear and tear. That is to say, they last longer and need replacing less frequently. Firms such as GSmach are putting a lot of effort into developing these new materials that are up to the high demands of contemporary manufacturing. There are also new designs for the screws themselves that could help in the mixing process. Better mixing produces higher-quality products, so that’s what every manufacturer would like to see.

Energy efficiency is also very much on the radar for new twin screw extrusion technology. Even machines that use less energy are not only good for saving money but also the planet. Developments in technology for motors and their control are driving down energy use. Gsmach insists on producing high performance machines which are environmentally friendly. Finally, the future for twin screw extrusion technology is automation. Automated systems can handle many jobs, making the machines less fickle to operate and less prone to human error. All these developments represent the bright future of twin screw extrusion and it is certainly on its way to making manufacturing faster, cheaper, and more dependable.

Where To Find Trusted Spares For Twin Screw Extrusion Line Upgrade?

It is important to replace components of a Twin Screw Extruder line in order to keep the machine in its proper operation. During the process of locating a dependable part, the right sources must be chosen to obtain one of high quality. The source should be where you start your search, according to a director of United States Public Interest Research Group known as Nathan Proctor. GSmach provides quality replacement parts which are compatible with their machines. However, once your order is separated with GSmach, you can be sure that the parts will be fitting and operating perfectly as before with your old equipment. This would go a long way in avoiding the problems that could occur due to the use of incompatible parts.

Find well-trusted suppliers that are extremely experienced in twin extruder parts is one option. Such sellers are typically able to sell a variety of parts, including screws and barrels, sensors, and controls. As usual, you should read the reviews and positioning of these suppliers before purchasing them. A reputable supplier will provide much information about their parts such as material as well as the machines to which the parts are compatible with. GSmach also works in collaboration with well known resellers to ensure that none of the parts is of inferior quality.

It is also prudent to seek the advice of professionals when it comes to upgrades. The name of the company is GSmach (said Jeesmash) and it has a consulting service where you can get some reasonably detailed advice on what parts to upgrade, and assistance with sourcing. Professionals would help to choose the components that will improve the performance and increase the longevity of your machine. Another thing to do would be to attend industry trade show. During these exhibitions, you will get to meet suppliers, view new products and get to know the latest in twin screw extrusion technology.

Quality where you want to use parts you can trust in your twin screw extrusion line upgrades, quality is of importance. Like in case of GSmach, you are not to remain loyal to your original manufacturers and have to go through known suppliers or have an expert view, it will brings good result to you-a life span of your machine.

Table of Contents

- What are Some of the Common Usage Problems Faced by Twin Screw Extrusion Lines in the Industry?

- Where to Purchase Professional Twin Screw Extrusion Lines at Wholesale Price?

- Which Maintenance Habits will help to Prolong the Lifetime of a Twin Screw Extrusion Line?

- Who's Pushing the Envelope on Success with Twin Screw Extrusion Technology?

- Where To Find Trusted Spares For Twin Screw Extrusion Line Upgrade?