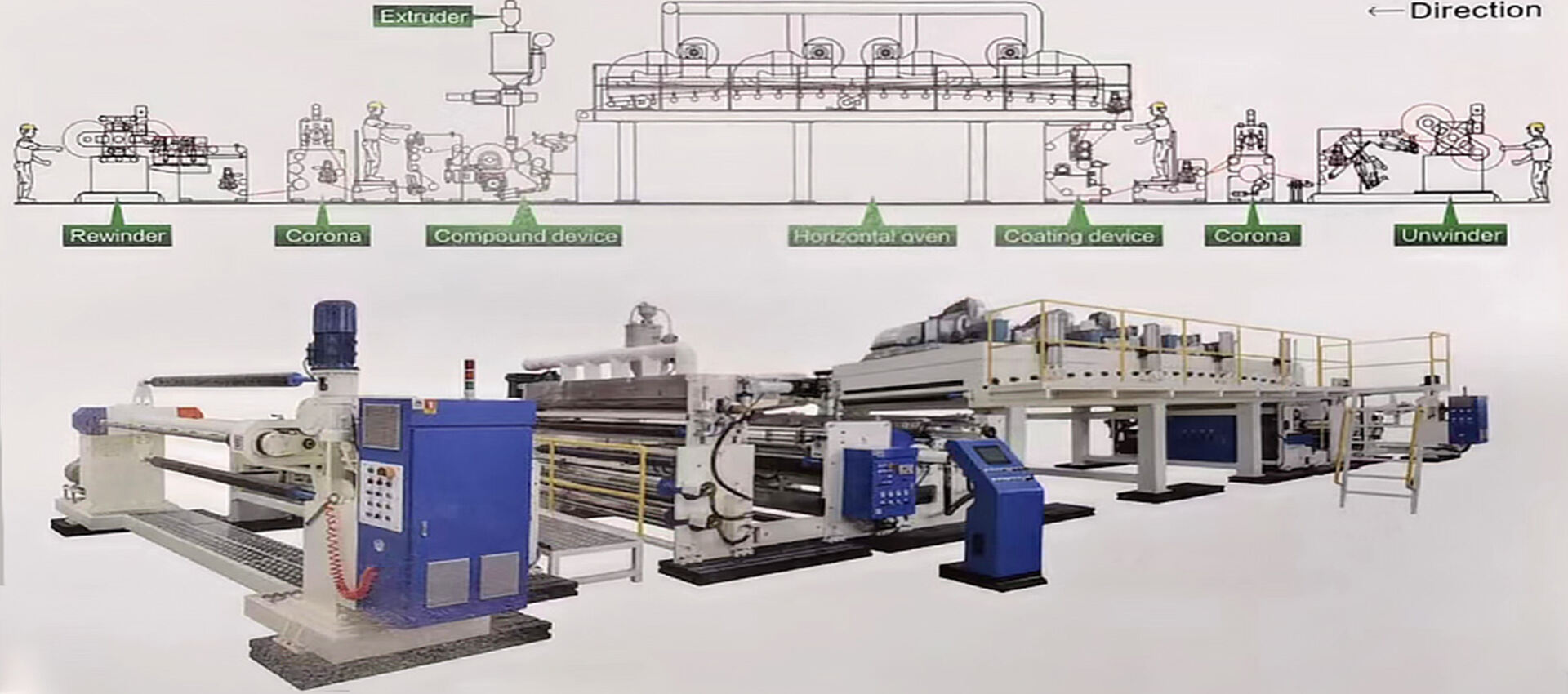

GSmach designs and manufactures extrusion laminating/coating

lines on the strength of a thorough expertise in the co-extrusion

of special polymers - customized and modular layout to meet the

demand for special products;

- chill-roll unit with precise temperature control - rapid cooling system

- special winders and unwinders suitable for any final application.

Thermal Film Extrusion Laminating Machine

Technical parameters

| Machine specification | 1200mm/1400mm/1700mm |

| Effective width | Max1100mm/1300mm/1600mm |

| Machine speed | 350m/min |

| Extruder | LD-90mm/LD-100mm “Automatic lifting type extruder” |

| Extruder power | 45-55kw |

| Extruder output | Max 200kg/h or 250kg/h |

| Used resins | Coated resins like LDPE/LLDPE/PP/EVA/EAA |

| Coating thickness | 8-45μm |

| Thickness uniformity | ≤±5% |

| Unwinding diameter | Max Φ1200mm |

| Rewinding diameter | Max Φ1200mm |

| Basic material | Paper(35-200g/㎡) |

| Tension control | Full automatic tension roller closed-loop constant tension control of unwinder and rewinder |

| Control mode | Human-machine interface, extrusion thickness is automatically precision calculated by computer, whole machine linkage control |

| Frequency converter | Imported AC digital vector control inverter |

| Machine Dimension(L*W*H) | 19.2/13.2×(9.5-12)×4.5m |

Main Features

1) Double Shaft-less paper roll stands suitable for 3-6 inch paper core,automatic lift ,easier operation .

2) Auto splicer device realize paper in 150-300 m/min speed exchange without decrease machine line speed

3) Ultrasonic type EPC system,makes frequent replacement materials operation more simple

4) Hydraulic lamination structure design , can make coating thinner and firm .

5) Trimming device make the finished coated paper rolls even

6)Special cutting knife and rewinder design makes high speed rewinding shafts exchange possible

Applications:

BOPP thermal film/ PET pre-coated film

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy