Get the Best Results With a Compounding Twin Screw Extruder

Do you think you are trying to find the dependable and mix method efficient process materials? the If full case, a compounding twin screw extruder can be what you should need, along with GSmach's product polyurethane film extrusion. Keep viewing for more information about it is many benefits. This machine several advantages and innovations that allow it to be the perfect chance for a number of applications.

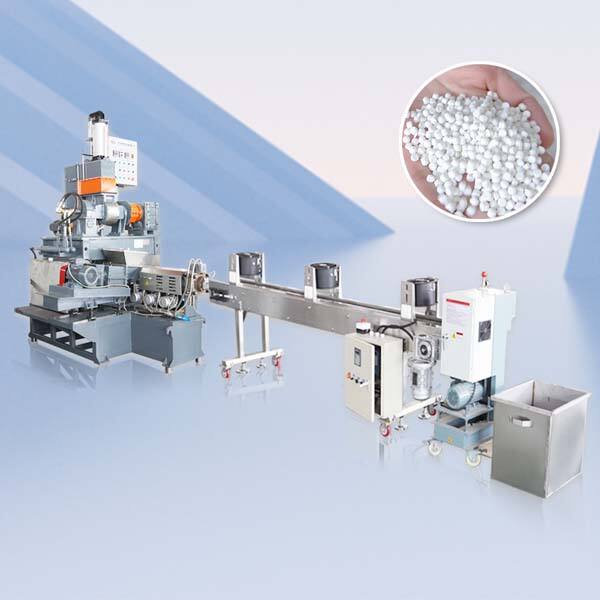

It may handle a wide variety of, including plastics, rubbers, powders, and pastes, amongst others, same with the compounding extruder produced by GSmach. The machine is also very efficient, permitting you to definitely save time and cash through getting the sum total results need in a shorter time as well as less waste. one of the main element top features of this machine is it is capability to reliably mixture materials, achieving an uniform mixture is free from lumps or inconsistencies.

The product consists of two screws that rotate in opposite directions, letting them mix and process materials with incredible accuracy, similar to the GSmach's product like pet pelletizing. The screws are created to make high shear, meaning the materials is thoroughly prepared and mixed. One of the more attributes of a compounding twin screw extruder is the genuine way it works.

A compounding twin screw extruder is an extremely safe machine to use, the same as barrier screw extruder built by GSmach. Its fashioned with multiple safety features, including sensors, alarms, and interlocks, to end accidents and protect operators. Whenever it comes down to gear and machines, safety should be a top issue. and, it is enclosed design means that there is minimal exposure materials, reducing the chance for contamination and dangers.

When there, the screws will start processing and mixing the materials, achieving the desired consistency quality, just like the GSmach's product called temperature control unit for extruder. You can adjust the speed, heat, as well as other parameters to get the full total outcomes you will require. To use the gear, you simply need to load the materials to the hopper, where they will be transported to your processing chamber. Making utilization of a compounding twin screw extruder is simple.

Let your production process be Compounding twin screw extruder by partnering with our expert professionals and designers. People are appropriate right here to help you through your challenges, maximizing the effectiveness of your production. You can expect 24/7 remote tech support team, using cutting-edge smart techniques.

Our machines are compliant with international standards for safety and quality offering Compounding twin screw extruder. You can save up to 40% as compared to other European suppliers. Our experienced team and multilingual service guarantee both high-quality products and unmatched client service.

We began operations in 2003 and are expert in the growth of polymer extrusion technology. People focus on top of twin-screw extruders we have successfully shipped over Compounding twin screw extruder. Our years of suffer from will offer you unfailing support.

GSmach is a frontrunner in China for extruded Polystyrene Equipment and is Compounding twin screw extruder with world-class companies like BASF, Owens Corning ISOFOAM Ravago and others. Our record of success demonstrates our commitment to excellence in delivering world-class industry leading companies.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy