When it comes to manufacturing items out of plastic, hips sheet extruders are machines that are very important. They assist companies in making all sorts of products — packages for toys, say, or containers for food. With the creation of these special machines, it became easier to make plastic sheets. Now, we’ll know how hips sheet extruder helps companies to work faster and better!

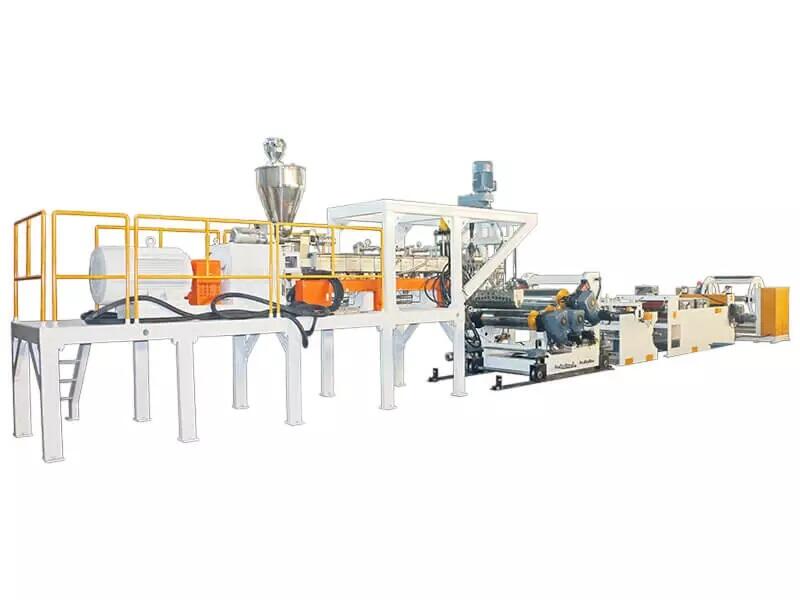

Hips sheet extruders are machines that heat up small plastic pellets and melt them down. The melted plastic is made into thin sheets, or strips of plastic that are useful for many things. Before there were hips sheet extruders, companies had to make plastic sheets by hand, and it took a long time and was really hard. Now with hips sheet extruders, companies can cheaply and easily produce masses of plastic sheet. This speeds up and improves the manufacturing process!

Hips sheet extruders are very versatile: It can produce plastic sheets in various sizes, thicknesses and colors depending on what a company requires. That’s because they can be used to make many things, including shiny wrappers for toys or tough packaging for food. Whether a company is looking for it, hips sheet extruders are able to help them create it!

One of the main reasons that hips sheet extruders are so valuable is because they are so commonly used in the packaging industry. Types of packaging that businesses use plastic sheets produced by hips sheet extruders to produce. These plastic sheets are lightweight, and have high strength and flexibility which makes it ideal as filter for protecting items such as toys, electronics, and food. Hips sheet extruder s enable firms in the industry to produce packaging that is durable and attractive!

Hips sheet extruder-9 With each passing year, hips sheet extruders have become even better at making plastic sheets. With new technology, they can now make sheets that are stronger, more flexible and better for the environment. This has led to the possibility of companies to produce better-quality products with plastic sheets made by hips sheet extruders Used pallet wrappers. With these breakthroughs, hips sheet extruders are becoming more and more vital in production!

Though hips sheet extruders are important, one must also consider their environmental impact. Producing plastic sheets can generate waste and consume a great deal of energy. But with the advent of new technology in hips sheet extruders, they are now more efficient and environmentally friendly. This allows companies to produce plastic sheets in a way that’s healthier for the planet. Responsible use of hips sheet extruders will help protect our planet for generations to come!

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with hips sheet extruder.

GSmach is a leader in China for extruded polystyrene equipment, collaborating internationally with renowned companies such as BASF, Owens Corning ISOFOAM Ravago and others. Your track record demonstrates our commitment to excellence in servicing global industry hips sheet extruder.

Our machines are compliant with international standards for safety and quality offering efficient solutions. You can save up to 40% as compared to other European suppliers. Our experienced team and hips sheet extruder guarantee both high-quality products and unmatched customer service.

Your skilled engineers and experts are available to greatly help you along your way. We're ready towards hips sheet extruder you overcome challenges and optimize your production effectiveness. We provide remote and seamless technical support using cutting-edge smart techniques.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy