When we think about fabricating stuff like toys, boxes or even car parts, we tend to think in terms of what materials we’re going to use. One method of manufacturing these items is sheet extrusion.

ABS sheet extrusion line technology is the one which makes sheets from a substance referred as ABS. ABS is a robust type of plastic. It is great for creating numerous types of everyday objects. The ABS sheet extrusion line is a large machine that takes ABS material and spits out flat sheets that can be formed into various products.

There are many advantages when using an ABS sheet extrusion line. For one thing, it helps factories make those large sheets of ABS fast. This is how they can make lots of product very quickly.” Plus, ABS is durable and resistant to damage, making it perfect for long-lasting products.

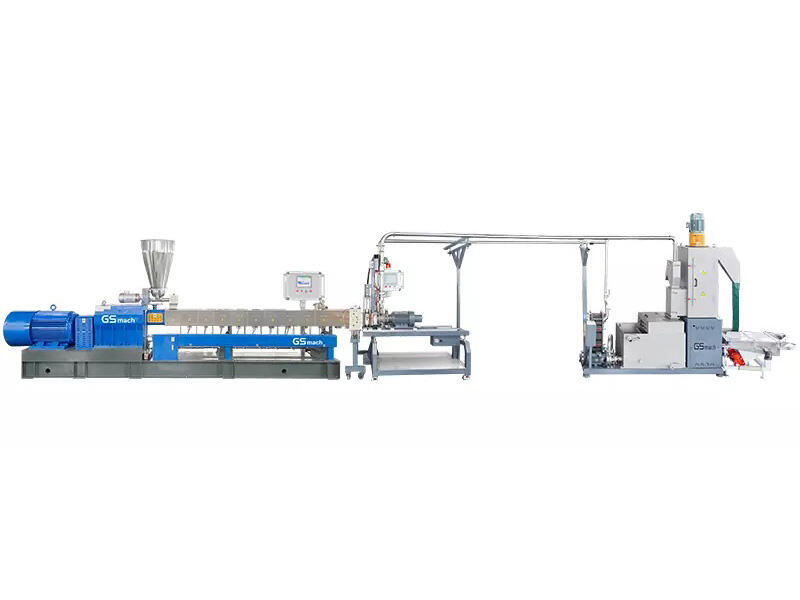

Parts of an ABS Sheet Extrusion Line An ABS sheet extrusion line has vital parts that function together to make the sheets. A crucial part is the extruder, which is essentially a large screw that melts the ABS and forces it through a mold to create a sheet. The cooling also matters. That aids in the cooling and hardening of the sheets after they are made. The other components, such as the cutting and the stacking systems, work to mold and organize the ABS sheets for additional work.

In order to make sure that an ABS sheet extruder line working well, you have to take care of it. That means keeping the machine clean and free of anything that could block it. It also involves reviewing the temperature and speed settings, ensuring they're adjusted correctly for the type of ABS every source will have different temperatures and speeds. Regular attention can prevent issues and keep your machine running smoothly.

As it happens, new developments in ABS sheet extrusion line technology will be making their way in as technology advances. That could lead not only to faster machines, but also to new methods of resizing and reshaping the ABS sheets. With such improvements, factory can make even more cool and high-quality products with ABS.

GSmach leads the market for abs sheet extrusion line in China, collaborating with renowned international companies such that BASF, Owens Corning, ISOFOAM, Ravago, and various others. Our track record proves our dedication to serving industry management around the world.

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with abs sheet extrusion line.

Empower your production journey with the experienced experts and engineers. We are right here inside help you abs sheet extrusion line and improve your production efficiency. We offer remote and seamless technical maintain using cutting-edge intelligent technology.

Our machinery adheres to international standards for safety and quality and offers abs sheet extrusion line. You can save around 40% when compared with the competitors. European companies. Our multi-lingual team and knowledgeable staff ensure that our customers receive the best services and products.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy