It is highly necessary to manufacture plastic boards carefully and high-efficiently in factories. GSmach is a high-tech company, and at the same time, we are the plastic boards production factory. This post, we are going to learn how does plastic board manufacturing works? How do the materials convert into a sturdy plastic board, and how to have better manufacturing process and reducing the waste of materials.

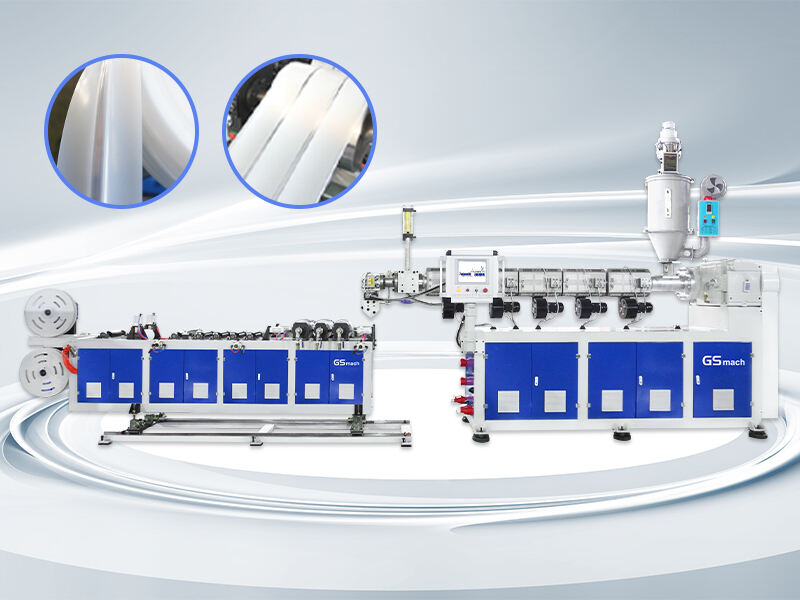

The production of the plastic board includes multiple steps to assure the quality of the boards. It begins with raw materials, including small plastic pieces known as pellets, placed into a device called an extruder. The extruder heats and melts the plastic pellets, then forces the melted plastic through a die opening into a flat sheet. Next, the sheet cools off and is cut to the size needed to create plastic boards. GSmach’s machine includes special tools to monitor and correct the process to ensure it is done perfectly and efficiently.

GSmach's machine adopts high technology that produce very strong recycled plastic boards. The machine has specific designs that can control to what thickness and shape the plastic boards are. It also includes cooling systems to ensure the boards cool appropriately after being cut. Together these technologies combine to make strong, consistent boards that are not only durable over time, but offer the same great look year after year.

The extrusion process transforms raw materials into durable plastic boards. The extruder works by heating and melting the pellets, forming melted plastic that can then be molded into a flat sheet. As the sheet cools, it turns into a hard, plastic board. This flow is what make GSmach plastic board strong and durable.

GSmach’s machine is intended to operate more efficiently and to minimize waste. It has smart controls that monitor and dial in the process while it’s happening to ensure production is optimized. GSmach can produce more plastic boards in less time by optimizing the extrusion process. It also recycles any excess plastic, cutting down on waste and benefiting the environment.

GSmach is the market leader in Asia for extruded plastic board extrusion line and is collaborating internationally with world-class firms including BASF, Owens Corning ISOFOAM Ravago and many more. Our track report demonstrates our dedication to serving leaders in the industry around their globe.

Our machines are created to ensure that they meet international safety and high standard of quality. We offer cost-effective solutions. You could salvage up to 40% once compared with competitors. European suppliers. Our multilingual team and specialist staff does make sure that customers receive that the plastic board extrusion line and products.

Produce your production more effective by working with the skilled specialists and engineers. We are here to simply help you overcome challenges and optimize your production's performance. We come with 24/7 remote tech support team utilizing their most plastic board extrusion line.

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with plastic board extrusion line.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy