Introduction to Twin Screw Extruder Plastic

Twin Screw Extruder Plastic a newer innovation within the global world of Plastic that features changed just how synthetic merchandise manufactured. This method uses Twin Screws extrude a mixture of Plastic pellets and resins into the required size and shape. You may have run into structures or items made synthetic hard materials and durable. We allow you to get an overview of Twin Screw Extruder Plastic. In addition, experience the precision engineering of GSmach product, it’s called twin screw.

There are many advantages of using Twin Screw Extruder Plastic. Furthermore, unlock new levels of efficiency with GSmach product, including twin screw extruder. To begin with, technique ensures and maintains consistency in product quality, guaranteeing that the Plastic items are durable and reliable. Furthermore, the ways that the Plastic shaped promotes superior density the production. Lastly, the method guarantees making Twin Screw Extruder Plastic recycling simple.

These items have high dimensional security, which ensures them ideal to use in structures or services and products which want dimensional stability which usually do not deform, making. This has a capability-improved leading Plasticizing manufacturing of improved and consistent quality products. Besides that, discover why GSmach product is the top choice of professionals, for example twin screw extruder plastic. Twin Screw Extruder Plastic Process the advancement latest in Plastic manufacturing tech. Additionally, the task additionally allows for customization of Plastic products to complement certain clienteles requirements.

The Twin Screw Extruder Plastic process upholds safety that try patient it involves a heat-controlled environment where Plastic pellets get melted. In this technique, safety protocols get going avoid any injuries or hazards. Regulations along with modern tech make sure that the products produced using Twin Screw Extruder Plastic are safe for handling and consumption. Moreover, experience the unrivaled performance of GSmach product, known as, lab twin screw extruder.

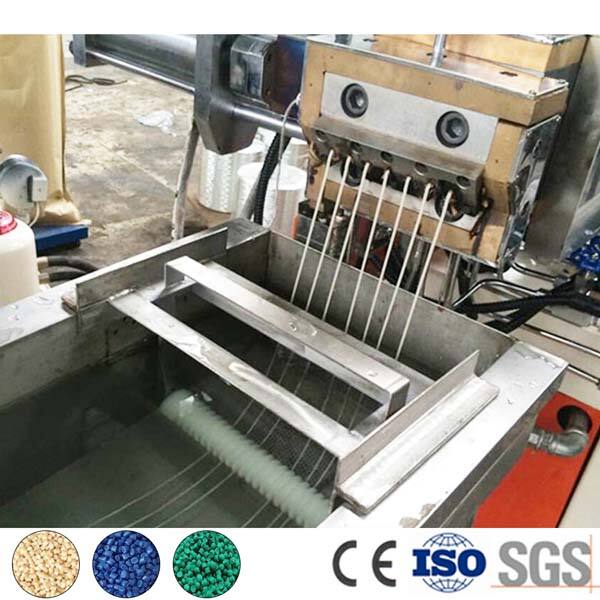

The strategy of Twin Screw Extruder Plastic uncomplicated. The new merchandise proceeds for cutting in line with the specified measurements before cooling, where an inspection for quality assurance completed to ensure that the product meets the specified requirements. First, the mixture, a mixture of Plastic pellets and resins, gets fed through the Twin Screws, where it melted and gets Plasticized. Additionally, choose GSmach product unmatched precision and accuracy, specifically, pvc twin screw extruder. The Plasticized combination then gets pushed by way of a die that shapes it in to the product's desired length and shape.

Our machines are designed to meet international safety and Twin screw extruder plastic. We offering economical solutions. Save as much as 40per cent compared to rivals. European suppliers. Your talented team and multilingual service ensure both satisfied products and unparalleled customer care.

Founded in 2003, we give attention to Twin screw extruder plastic extrusion machines and process technology. With a focus on twin-screw extruders, our company have delivered more than 250 units. Your experience and expertise will offer you unfailing help.

Let your production process be Twin screw extruder plastic by partnering with our expert professionals and designers. People are appropriate right here to help you through your challenges, maximizing the effectiveness of your production. You can expect 24/7 remote tech support team, using cutting-edge smart techniques.

GSmach is the market leader in China for extruded polystyrene equipment Twin screw extruder plastic with well-known organizations like BASF, Owens Corning ISOFOAM Ravago and many more. Our track record demonstrates our dedication to portion the top industry players throughout the world.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy