Cool things to make out of plastic: Use Twin Screw Extruder Technology. You’ve got these two great big screws that turn and push the plastic through a big machine and make it into whatever you want. This process is how we manufacture all kinds of plastic objects, from toys and bottles to parts for cars and planes.

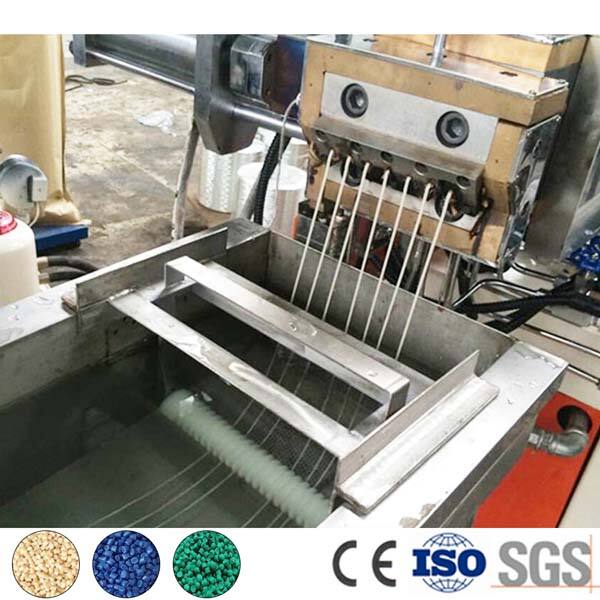

Twin screw Wholesale plastic extruder technology is an interesting process, by which two intermeshing screws rotate to melt, mix and shape plastic material. Though the screws serve the same purpose, each works together to push the plastic into the machine, heating and molding the plastic into the product’s shape. It's the same technology the plastic industry employs to produce the myriad of items available.

There are a lot of advantages in the utilization of twin screw extruders for plastic extrusion. One of the key benefits of this is better mixing and consistency in the material and the resulting product. Twin screw extruders can process a variety of materials, so that the application can be adapted to a variety of purposes. They also come with faster production rates to enable businesses to keep pace with their manufacturing requirements.

Progress in twin screw extruder plastic machinery has only made the process more efficient and better for the environment. Innovative technologies have been created for better mixing, higher production and lower energy consumption. By doing so these improvements have resulted in less and less expensive machines, which has enabled Lab Twin Screw Extruder to be used in the laboratory, R&D and industrial production warming up to other industries.

Twin screw extruders have found extensive application in the plastics industry. They are widely used to make plastic pipes, tubing, hoses, and profiles, including vinyl hoses and profiles for the automotive and construction industries. Furthermore, twin screw extruders are involved in the compounding of plastic materials combining various additives and fillers with the base resin. This is one way to produce compounds which improve the characteristics of the plastic and even develop the material for particular needs.

The machine parameters need to be optimized for twin screw processing systems in order to achieve optimal performance. This makes adjusting the temperature, RPM, and density even more important to control the process of the plastic better. Regular servicing and cleaning of the machine is also important to ensure it works well and does not break down. Adhering to these best practices, businesses are optimizing their production output and new plastic products.

GSmach is a frontrunner in China for extruded Polystyrene Equipment and is Twin screw extruder plastic with world-class companies like BASF, Owens Corning ISOFOAM Ravago and others. Our record of success demonstrates our commitment to excellence in delivering world-class industry leading companies.

We began operations in 2003 and are expert in the growth of polymer extrusion technology. People focus on top of twin-screw extruders we have successfully shipped over Twin screw extruder plastic. Our years of suffer from will offer you unfailing support.

Our equipment meets Twin screw extruder plastic of safety and quality offering low-cost possibilities. Save yourself as much as 40% when compared with competitors. European suppliers. Our experienced team and multilingual service ensure you a high quality product and unmatched customer service.

By using cutting-edge, smart control systems user offer seamless, remote and valid technical support to make sure your Twin screw extruder plastic. Your skilled engineers and specialists are here to aid you to your journey. We are prepared to merely help you through challenges, enhancing the performance of your production.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy