Extrusion Coating Lamination Plant: The Future of Safe and High-Quality Packaging

But instead of sandwiches, we're talking about packaging materials like food bags, boxes, and containers. Would you know what extrusion coating lamination is? I want to explain it’s like putting a layer this is protective top of sandwich to help keep it fresh longer. To be a total result, ECL has develop into a popular type of production in lots of industries. extrusion coating lamination (ECL) is a procedure that combines different materials into one strong and durable package which makes it ideal for transport of GSmach extrusion coating lamination plant.

Additionally, ECL enables for precise thickness control over each layer, which affects the package's energy and flexibility. Precise thickness control, with the strength and durability of ECL packaging, helps GSmach screw extrusion is the optimal decision transporting. For example, paper on one side and plastic on the other will give you the package with a barrier against moisture, while aluminum on one part and plastic about the other supplies the package with a barrier against light and air. One of the advantages of ECL is it enables the combination of various materials – like paper, plastic, and aluminum – generate a package with unique properties.

here are various advancements the ECL procedure that have actually enhanced packaging quality like the development of newer machinery and equipment which have actually revolutionized the way in which we produce packages. For example, the application of multi-layered co-extrusion technology has allowed for the creation of stronger packages, with improved heat-sealing capabilities, providing better security for the items inside. Furthermore, advancements in printing technology have actually managed to make GSmach extrusion coating lamination feasible to personalize graphics which may be printed right on the surface of the packages, bringing branding and promotional abilities up to a new level. Innovation is just a big part of the ECL manufacturing, and it is important in enhancing the typical associated with the packages produced.

Furthermore, ECL packages were created to be recyclable, what this means is they do not donate to landfill waste. ECL is an eco-friendly choice GSmach sheet extrusion generates use of fewer materials and produces less waste compared to other forms of packaging. In addition to quality, safety is a critical aspect of manufacturing. Consumers deserve packaging perhaps solutions not only safe but additionally environmentally friendly.

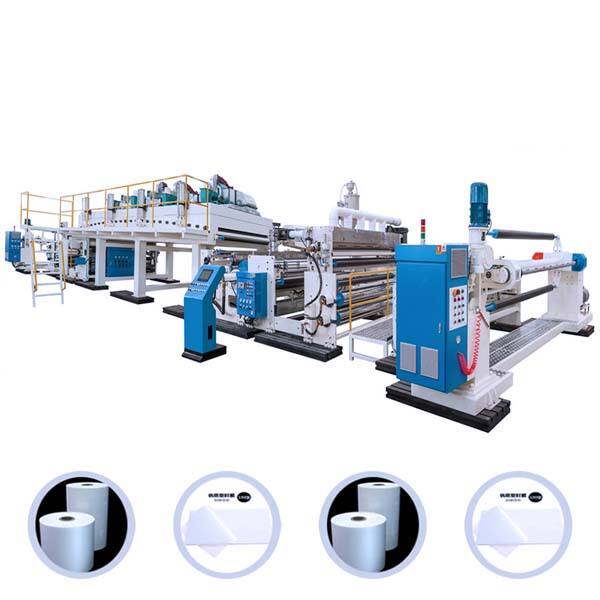

The entire procedure of having an ECL plant involves combining different levels of material to produce a package with particular properties. This procedure is completed using a co-extrusion machine, which typically involves four channels: unwinding, extrusion lamination, cooling, and winding.

ECL packages are created using different levels as synthetic, adhesives, aluminum, and paper. These layers are fed through the unwinding station and then the rollers and cooling chambers every one of the levels together. Co-extrusion refers towards the entire process of numerous layers of GSmach extrusion of film while they truly continue to be in a melt state. The materials are then passed through various rollers and cooling chambers make a great and durable package. These procedures bring about a quality both package durable and flexible.

Our expert technical engineers and technicians are available to assist you to your journey. User're right here to help you overcome obstacles and improve might Extrusion coating lamination plant of your production. People offer 24/7 remote technical maintain with cutting-edge, intelligent technology.

Established in 2003, we focus on polymer extrusion machines and process Extrusion coating lamination plant. We've delivered a lot more than 2,500 twin-screw devices. Our years of experience will provide you with unwavering support.

Our machines are compliant with international standards for safety and quality offering Extrusion coating lamination plant. You can save up to 40% as compared to other European suppliers. Our experienced team and multilingual service guarantee both high-quality products and unmatched client service.

GSmach is the leading company in China for extruded Polystyrene Equipment and is collaborating internationally with world-class organizations like BASF, Owens Corning ISOFOAM Ravago and others. Our history shows our commitment to excellence in Extrusion coating lamination plant leaders.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy