What is a Parallel Twin Screw Extruder?

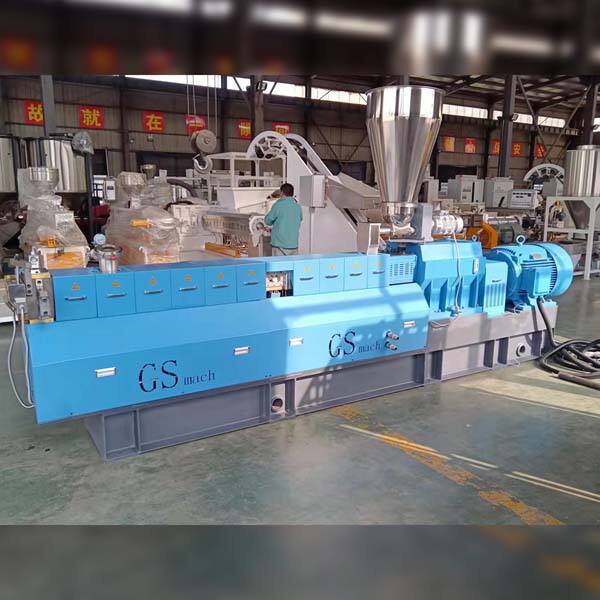

A screw that is synchronous is twin is simply a device used to process and mix garbage. GSmach parallel twin screw extruder offers and come together to feed, melt, and mix the materials before extruding them right into a desired shape. This technique can be employed within the manufacturing industry to help make products like plastic pipes and sheets.

One of the major top features of using a parallel twin screw extruder is its ability to process materials of various viscosities and properties. GSmach parallel twin screw can handle materials ranging from low viscosity to high viscosity. Additionally, this machine can control the shear heat rate during the mixing process, resulting in high-quality products.

In recent years, parallel twin screw extruders have undergone various technological advancements. GSmach twin screw extruder manufacturers have incorporated a smart control system that automatically adjusts the machine's settings based on the material being processed. This not only saves time but also reduces the likelihood of human error with the twin screw extruder.

Parallel Twin Screw Extruder now offer intermeshing or co-rotating screw designs, which help in more efficient conveying and processing of materials. This leads to high-quality products and reduces waste.

As with any equipment, safety is crucial. Users of twin screw extruders need to be properly trained and educated on how to use the GSmach twin screw safely.

Parallel twin screw extruders have diverse applications including pharmaceuticals, food processing, synthetic materials, and others. The GSmach twin screw extruder machine can help in producing a wide range of products, from simple plastic pellets to complex medical items.

When purchasing a parallel twin screw extruder, it's critical to choose a manufacturer that offers excellent after-sales service, including technical support, maintenance, and repair services. This will help ensure that the machine's users have fruitful and effective operation for years to come.

GSmach is a leader in China for extruded polystyrene equipment, collaborating internationally with renowned companies such as BASF, Owens Corning ISOFOAM Ravago and others. Your track record demonstrates our commitment to excellence in servicing global industry Parallel twin screw extruder.

We were established in 2003 and concentrate on polymer extrusion machines and Parallel twin screw extruder. We've shipped more than 2,500 double screw units. Rely in our vast expertise and nonstop help for your extrusion needs.

Our equipment is in line with international standards of safety and quality offering affordable solutions. Enjoy significant savings, as high as 40% in contrast in order to other European suppliers. Our multilingual team and expert employee will ensure that customers receive the Parallel twin screw extruder and service.

The team of experts and engineers will likely get there to assist you in your Parallel twin screw extruder. We're prepared to simply services you overcome obstacles and improve your production performance. Currently remote and seamless technical support with cutting-edge, smart techniques.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy