PE sheet extrusion machines are awesome machines that make plastic junk. They have a lot of parts that all have to work together to form sheets of plastic from PE. Read on to find out how they work, why they are great and more!

PE sheet extrusion machines are just a big Play-Doh machine. They take little nubbins of PE, a type of plastic, and squeeze them through into long, flat sheets. This sheet will cool off, and you can use it to create all sorts of things, like bags, containers, and yes, toys! It’s incredible how they turn little pieces of plastic into something practical.

Prior to PE sheet extrusion by machines, it has been difficult to make the plastic things and it usage to take very long time. But now, using these machines, factories can produce plastic sheets faster and more easily. That means more plastic stuff can be made fast, helping to satisfy the heavy demand for plastic products.

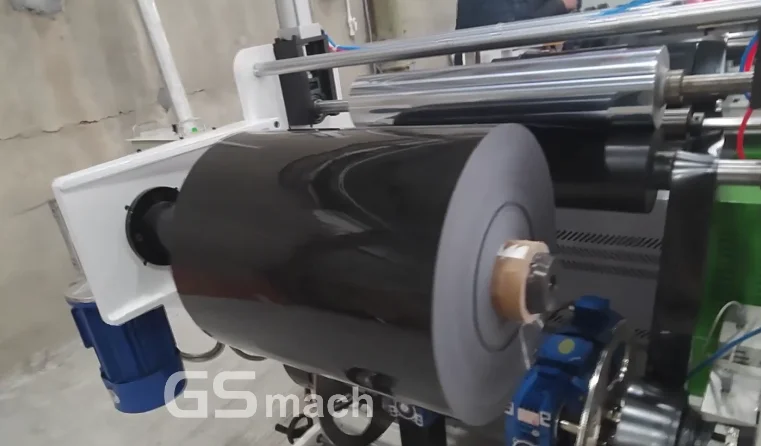

There are many parts to PE sheet extrusion machines, and it is part of the reason why everything works the way that it does. There’s a hopper where the small PE pieces enter, an extruder that melts the plastic, and a die to transform the plastic into a sheet. And then there’s a cooling system that brings the sheet to a temperature, and then you can cut it in the right size. All these pieces work like a team to form the finished article.

There are numerous reasons for which the PE sheet extrusion machine isideal for use. It’s also faster and cheaper than other methods of producing plastic sheets. It also produces high-quality sheets that are robust and long lasting. And, these machines can be adjusted to produce sheets in a range of sizes and shapes, offering manufacturers a variety of options. All in all, using a PE sheet extrusion machine makes sense for companies that are interested in making plastic more efficient.

There are many applications of PE sheets manufactured from the extrusion machines. They can create packaging materials, such as bags and containers. They are also employed in construction to create pipes, insulation and roofing materials. The making of car parts also use PE sheet. The PE sheet has wide applications, which has ensured that they remain a vital material in numerous sectors.

GSmach is foremost industry for extruded polystyrene machines in China and is collaborating with top international companies such that pe sheet extrusion machine, Owens Corning, ISOFOAM, Ravago, and many the others. Our record shows our commitment to serving industry leaders around the entire world.

Our machines are compliant with international standards for safety and quality offering pe sheet extrusion machine. You can save up to 40% as compared to other European suppliers. Our experienced team and multilingual service guarantee both high-quality products and unmatched client service.

Let your production process be pe sheet extrusion machine by partnering with our expert professionals and designers. People are appropriate right here to help you through your challenges, maximizing the effectiveness of your production. You can expect 24/7 remote tech support team, using cutting-edge smart techniques.

We started operations in the end of 2003 and concentrate on the process of polymer extrusion. With a concentrate on pe sheet extrusion machine extruders, we have successfully delivered over 250 units. Our extensive experience can incorporate you with unmatched support.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy