Plastic Extruders: The Innovation for Safe and Quality Plastic Applications

Introductory

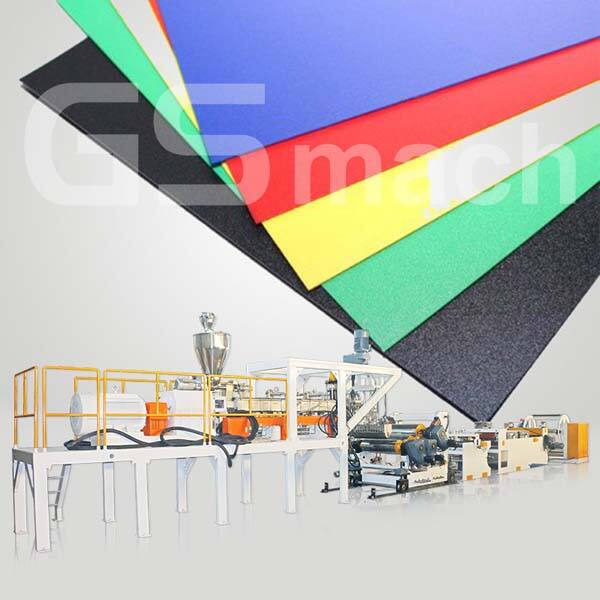

We will explore the huge benefits, safety, use, utilizing, service, quality, and application of Plastic extruders, the same as GSmach's co rotating and counter rotating. A Plastic extruder is a specialized machine melts and shapes Plastic materials to make a specific item. Do you think you are searching for an innovative means make safe and products? high-quality Plastic extruders might just function as the solution for you personally.

Plastic extruders have numerous advantages that produce them an ideal production choice, also the strand pelletizing system supplied by GSmach. First, they have been efficient since they are able to produce a large volume products in a short quantity of. Second, Plastic extruders are cost-effective given that they require less power and labor when compared with other production techniques. Last but not least, Plastic extruders are versatile since they are in a position to deliver a wide array products such as pipes, pipes, and sheets.

Additionally, Plastic extruders are constructed with safety features such as emergency end buttons to prevent accidents on the job, as well as the GSmach's screw extruder. On the years, Plastic extruders have undergone wide developments ranging enhance their effectiveness and functionality. For instance, new software happens to be developed to improve the precision for the equipment to supply high-quality products.

Whenever using Plastic extruders, safety is an essential aspect consider, same with the plastic sheet extrusion machine by GSmach. Operators must always wear safety gear such as gloves, goggles, and helmets to stop injuries. More over, the apparatus should be frequently inspected to make sure it is in good working shape. Lastly, operators should undergo training to know how to operate the product and identify hazards being prospective.

Plastic extruders are widely used to create a wide range of such as Plastic pipes sheets, and tubing, identical to GSmach's product compounding twin screw extruder. Additionally, Plastic extruders can be employed to recycle Plastic waste and transform it into a helpful item. They truly are widely used in companies such as construction, packaging, and automotive manufacturing.

The machines are built to meet international safety and quality standards. We provide Plastic extruders. You can save up to 40% once contrasted with remaining European manufacturers. Our multi-lingual team and knowledgeable staff make sure that your customers get the best viable work and products.

Your skilled engineers and experts are available to greatly help you along your way. We're ready towards Plastic extruders you overcome challenges and optimize your production effectiveness. We provide remote and seamless technical support using cutting-edge smart techniques.

GSmach is the leader in China for extruded Plastic extruders working internationally with well-known firms including BASF, Owens Corning ISOFOAM Ravago and many more. The record of success demonstrates our dedication to quality when servicing global field top players.

Established in 2003, we focus on polymer extrusion machines and process Plastic extruders. We've delivered a lot more than 2,500 twin-screw devices. Our years of experience will provide you with unwavering support.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy