Ever wondered how those clear plastic sheets that are used as panes in greenhouses, as lightweight barriers or for skylights are made? Well, it can all be attributed to a wonderful thing called extrusion. This time, let's see how PC hollow sheets are made effectively with a machine in the PC hollow sheet making machine factory today.

The PC hollow sheet is glassy, lightweight, durable, impact resistant, weighing light, impact resistance, and can work in the temperature range of -40-120 degrees. These (as well as other desirable chemical and physical properties) render them ideal for many diverse uses, ranging from construction and agricultural to packaging and transportation uses. Thanks to the adaptable nature of PC hollow sheet extrusion line, manufacturers can choose to produce this kind of sturdy sheets in different sizes, thickness and shapes to accommodate their particular needs.

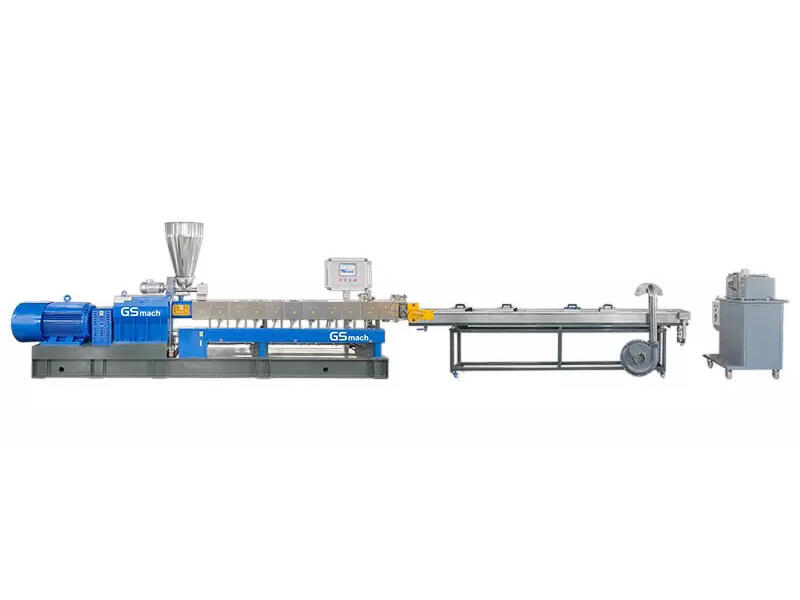

The secret to good quality PC hollow sheet is the machine. This is where the PC hollow sheet extrusion line comes into play. That machine is so advanced that it has all fittings and functions to make sure the extruding sheets are not only clear and even thickness, but also free of bubble, waping etc. With the ability to schedule and control temperature, pressure and velocity, manufacturers know that every sheet that comes off the extrusion line will meet great quality.

Efficiency is the name of the game in manufacturing. And in the production of PC hollow sheet, manufacturers want a simple process that can ensure not only the quality but also lower the cost. The PC hollow sheet extrusion line is specifically made for that. This machine is designed to streamline many of the steps in sheet extrusion, saving manufacturers time and labor, while also significantly increasing productivity. Also, since the portion of the amount of the raw material is used, waste can be suppressed, and the cost of the production can be reduced.

The machinery which has to be manufactured with even higher precision, in order to meet the requirements of the continuously improving technology, drives the advances of technology. PC hollow sheet extrusion line is no exception. This machine opens up new areas of application like never before with the most advanced technology and feature, lets you step into new possibilities for PC hollow sheet production. Whether that be with the latest materials, innovative designs or higher running speeds, the extrusion line offers manufacturers countless opportunities to produce the best in PC hollow sheets that today's market can ask for.

Our machines are designed to meet international safety and pc hollow sheet extrusion line. We offering economical solutions. Save as much as 40per cent compared to rivals. European suppliers. Your talented team and multilingual service ensure both satisfied products and unparalleled customer care.

We began operations in 2003 and are expert in the growth of polymer extrusion technology. People focus on top of twin-screw extruders we have successfully shipped over pc hollow sheet extrusion line. Our years of suffer from will offer you unfailing support.

GSmach leads the market for pc hollow sheet extrusion line in China, collaborating with renowned international companies such that BASF, Owens Corning, ISOFOAM, Ravago, and various others. Our track record proves our dedication to serving industry management around the world.

Enable your production journey by working with our skilled designers and experts. We're ready to assist you through any challenges and pc hollow sheet extrusion line of your production. Leveraging cutting-edge intelligent get a handle on systems, people provide seamless, remote and valid technical assistance, making sure your production operates efficiently.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy