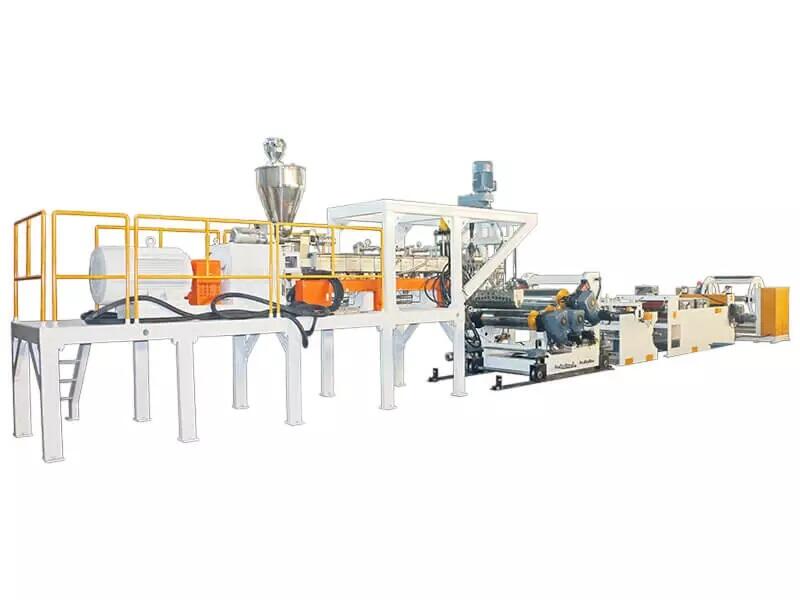

If we create stuff or toys, banners and packaging, the machine known as ABS sheet extruder comes in handy. This device produces flat sheets of strong and long-lasting ABS plastic. Now let's consider how acrylonitrile butadiene styrene sheet extruders function and why they matter in product creation.

An ABS sheet extruder takes small plastic pellets and melts them. Then, the melted plastic is forced through a mold to form a thin sheet. This is referred to as extrusion. The machine is able to produce various size and thickness sheets for different projects. These sheets can further be cut and shaped into various products.

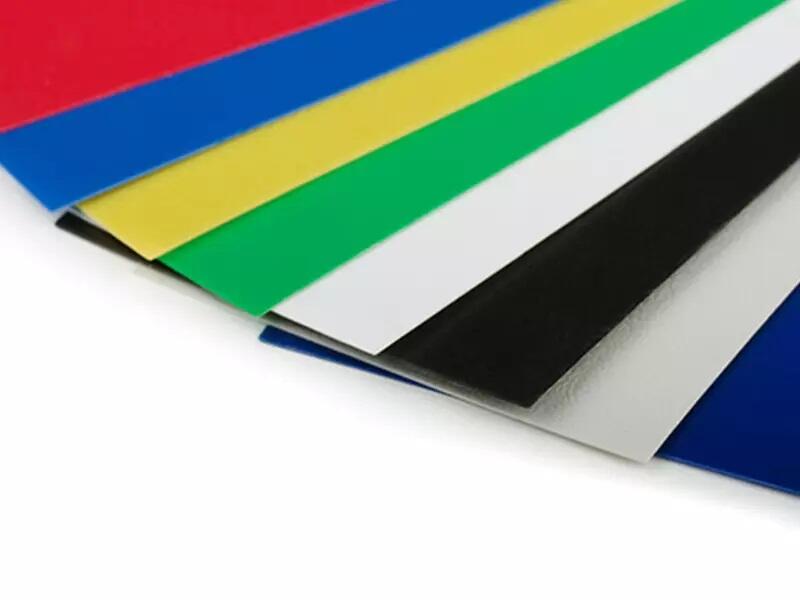

ABS sheet is a good one because it is strong and light and and easy to carve. They can withstand high levels of heat and are impervious to chemicals, making then fairly versatile for various applications. Using ABS sheets can help cut waste by being recycled into other new products.

If you’re choosing an ABS sheet extruder for your needs, consider the size and thickness of the sheets you’ll be requiring. Small sheets can be made on some machines, and other machines can make larger ones. Find a machine that is simple to work and maintain to ensure you can do your best work.

ABS Sheet Extrusion is applied in a range of applications; automotive, electronics and construction. They find use in car dashboards, and interior components. In electronics, they produce casings for computers and TVs. In construction, ABS plastic sheets are used for signs and displays. ABS plastic sheets are incredibly popular as they can be applied in a cushily.

There can be issues at times when using an ABS sheet extruder. One issue is air bubbles that can form in the sheet and make it weak. In order to avoid this problem, the machine operators need to monitor the temperature and pressure. Another problem is the sheet’s adhesion to the mold, which can lead to tears. To prevent this, clean and lubricate the mold frequently.

Your machines are designed to stay in line with overseas safety and standard of quality. We offer affordable solutions. Save as much as abs sheet extruder with other European manufacturers. Our skilled team and multilingual service ensure both happy appliances and unbeatable customer service.

GSmach is the leading company in China for extruded Polystyrene Equipment working internationally with well-known companies like BASF, abs sheet extruder ISOFOAM Ravago and many more. Our record shows our commitment to serving leaders in the around all world.

We were established in 2003 and focus on polymer extrusion machines and process technology. People have delivered more versus 2,500 twin-screw devices. Our years of experience provides you with abs sheet extruder.

Enable your production journey by working with our skilled designers and experts. We're ready to assist you through any challenges and abs sheet extruder of your production. Leveraging cutting-edge intelligent get a handle on systems, people provide seamless, remote and valid technical assistance, making sure your production operates efficiently.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy