Hey there! So today we are going to discuss something really cool and it is called the PP honeycomb board extrusion line. And if you’re not sure what that means yet -- don’t sweat it, we’ll explain it in lay terms!

Application The PP honeycomb board extrusion line is an extruder which produces the honeycomb board out of the material known as polypropylene (PP). A honeycomb board is a durable, lightweight material that appears like a beehive (the kind bees build) when you view it very closely. Heat and pressure on the extrusion line transform melted PP into sheets of honeycomb boards. These are boards with various uses.

PP honeycomb board has many benefits! For one thing, they are super strong and can hold an amazing amount of weight without themselves being all that heavy. That makes them perfect for construction, in which they can be made into walls, floors and even furniture. They are also nice for shipping, as they keep breakable things from shattering in transit without adding too much weight.

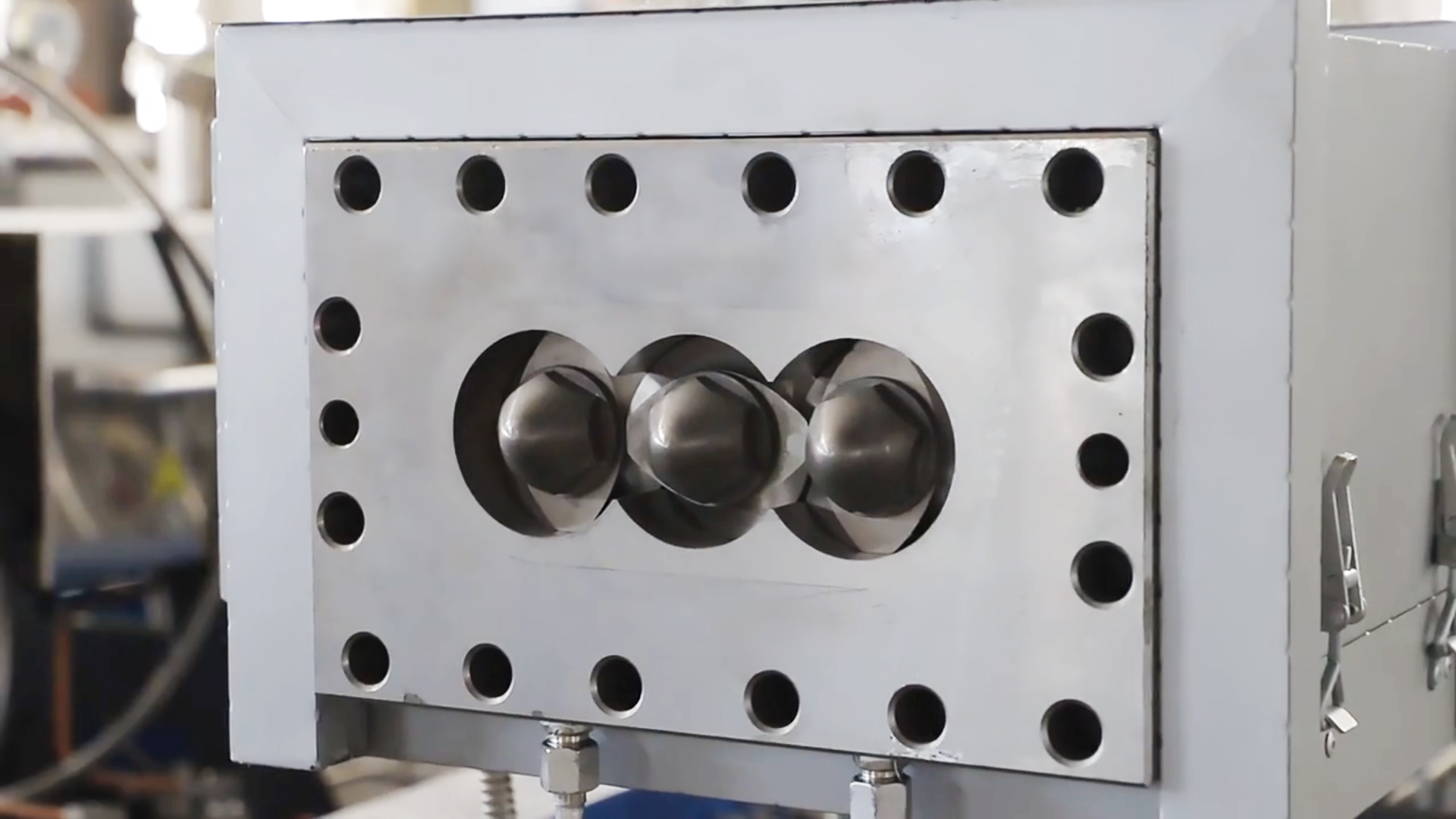

The extrusion line is composed of various machines cooperating to manufacture honeycomb boards. The PP pellets are first melted by an extruder. Next, the molten PP is extruded through a special form known as a die in order to get the desired honeycomb shape. The boards are then cooled and cut to size with special machines. It’s so neat, a great big puzzle and each machine has a special job!

You have to get the temperature and the pressure right during the extrusion process to make sturdy honeycomb boards. This ensures the boards are sturdy and durable. The extrusion line is also equipped with special sensors that help ensure everything runs smoothly. In so doing, we can start to design honeycomb boards that are both strong and light and really ease of use.

pp honeycomb boards can be applied to various industry. They are good for construction, cars, furniture and signs. And they’re good for the environment, to boot. They are light, requiring less energy to transport, and they are recyclable after use. This makes them an appropriate option for companies that value the planet.

We started operations in 2003 and specializes in their science of extrusion using polymers. We have supplied increased than 2,500 pp honeycomb board extrusion line. Our vast experience gives you unwavering assistance.

GSmach is foremost industry for extruded polystyrene machines in China and is collaborating with top international companies such that pp honeycomb board extrusion line, Owens Corning, ISOFOAM, Ravago, and many the others. Our record shows our commitment to serving industry leaders around the entire world.

Our equipment is in line with international standards of safety and quality offering affordable solutions. Enjoy significant savings, as high as 40% in contrast in order to other European suppliers. Our multilingual team and expert employee will ensure that customers receive the pp honeycomb board extrusion line and service.

By using cutting-edge, smart control systems user offer seamless, remote and valid technical support to make sure your pp honeycomb board extrusion line. Your skilled engineers and specialists are here to aid you to your journey. We are prepared to merely help you through challenges, enhancing the performance of your production.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy