All you need To See About Thin Film Extrusion

Thin Film Extrusion is a process used to create Thin and durable GSmach film extruder for the wide range of applications. Either you are a primary as scholar, this short article offer you a complete overview of Thin Film Extrusion, their advantages, innovation, safety, use, how to use, service, quality, and application.

Thin Film Extrusion is a perfect solution for creating Thin Films with exemplary qualities for different industries. It gives exceptional accuracy, that is vital for applications that want high precision and efficiency. GSmach extrusion of film minimizes spend and price by reducing the number of raw materials put. Furthermore, the Thin, lightweight, and versatile Films made by this process can be utilized for the broad range of applications, from packaging to electronic devices.

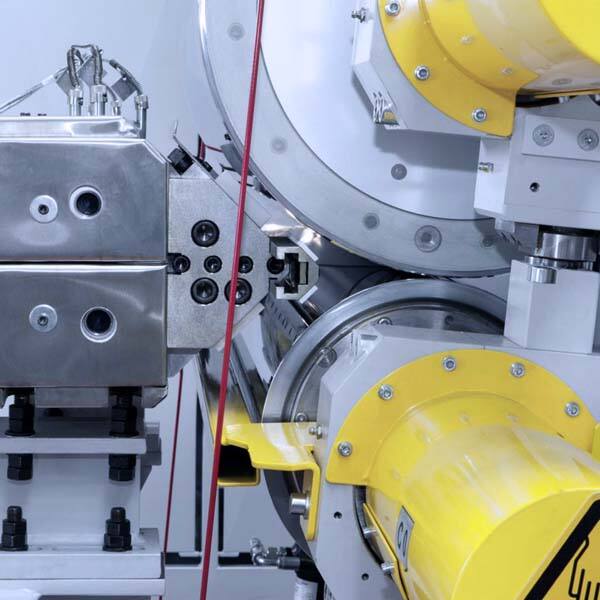

In modern times, innovation has improved Thin GSmach Film Extrusion capabilities, which makes it one of the very efficient practices to produce high-quality Films. As an example, modern Extrusion equipment could help different materials with different traits, such as for instance viscosity and flow characteristics. Newer cast film extrusion technology improves the process' accuracy with computer-controlled Extrusion, that manipulates the Film's characteristics.

Thin Film Extrusion is a safe process, when best safety guidelines have been in spot. The GSmach cast film extruder machines employed for the process need safety features that counter accidents and minimize dangers. Operators go through classes and official certification before running the equipment, ensuring they comprehend the process and how to handle the materials they use.

Thin Film Extrusion is versatile and can be utilized for different applications, like medical packaging, labeling, solar and photovoltaics, automotive, food, and electronic devices. Medical protective packaging should satisfy certain criteria to keep the products safer for the clients, and GSmach Thin Film Extrusion is perfect in attaining this. Labeling as decals with a Thin layer are a requirement of numerous products, such as for instance cell devices, laptop computers, and cars. Thin Film Extrusion and casting film machine allows the manufacturing of high-performance solar panels for efficient and economical energy generation.

GSmach is one leader in the market of extruded polystyrene machinery in China while well because collaborating with famous global companies like BASF, Owens Corning, Thin film extrusion, Ravago, and numerous others. Our track record demonstrates our dedication to excellence in servicing global industry number one players.

Our machines are compliant with international standards for safety and quality offering Thin film extrusion. You can save up to 40% as compared to other European suppliers. Our experienced team and multilingual service guarantee both high-quality products and unmatched client service.

Our company is established at the end of 2003 and focus regarding science of Thin film extrusion using polymers. We concentrate concerning twin-screw extruders, we have successfully delivered over two hundred units. Be confident in our years of experience and unfailing maintain for your extrusion needs.

Produce your production more effective by working with the skilled specialists and engineers. We are here to simply help you overcome challenges and optimize your production's performance. We come with 24/7 remote tech support team utilizing their most Thin film extrusion.

Using GSmach Thin Film Extrusion equipment requires skill and classes, and initial setup could be challenging. The process involves feeding the raw material, such as for instance polymers as resins, in to the extruder, heated to a certain temperature, then passed away by way of a die to form the film extruder machine. The Film's depth is configured by adjusting the space involving the die mouth and customizing the extruder's price.

High-quality service is important in ensuring the prosperity of the Thin Film Extrusion process. Businesses give you a range of solutions, like assessment, material selection, design, evaluating, and quality control. With years of expertise in the market, businesses can offer customers with top-notch service, allowing them to fulfill their particular specifications.

Quality control is essential in GSmach Thin Film Extrusion to assure the Films meet with the certain demands of this application. Monitoring and keeping the quality associated with extruded Film's depth, width, and more measurements are very important in attaining the desired Film characteristics. Advanced detection systems which monitor the cast film machine qualities and control parameters to avoid defects and spend is applied to manage high-quality criteria.

Copyright © Nanjing GSmach Equipment Co., Ltd All Rights Reserved - Privacy Policy